Do heat sinks radiate heat? This question might seem straightforward, but the answer is not as simple as one might think. Heat sinks are a critical component in thermal management systems, used to dissipate heat generated by electronic devices. However, the way heat sinks function is not well understood by many. In this article, we will delve into the intricacies of heat sinks and explore the concept of whether they radiate heat or not. Join us as we unravel the mystery behind this crucial component in thermal management.

Understanding Heat Sinks

What are Heat Sinks?

Heat sinks are passive thermal management devices designed to dissipate excess heat generated by electronic components, such as processors, power semiconductors, and other high-power devices. The primary purpose of a heat sink is to enhance the rate of heat transfer from the source to the surrounding environment, thereby maintaining safe operating temperatures and preventing thermal-induced failures.

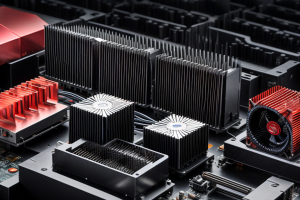

There are various types of heat sinks, each suited for specific applications and requirements. Some common types include:

- Natural convection heat sinks: These are the simplest type of heat sinks, relying on air or gas flow to dissipate heat. They are commonly used in small applications or low-power devices.

- Forced convection heat sinks: These heat sinks use fans or other means to force air or gas to flow over the heated surface, enhancing heat transfer. They are commonly used in high-power applications, such as CPU coolers or server cooling systems.

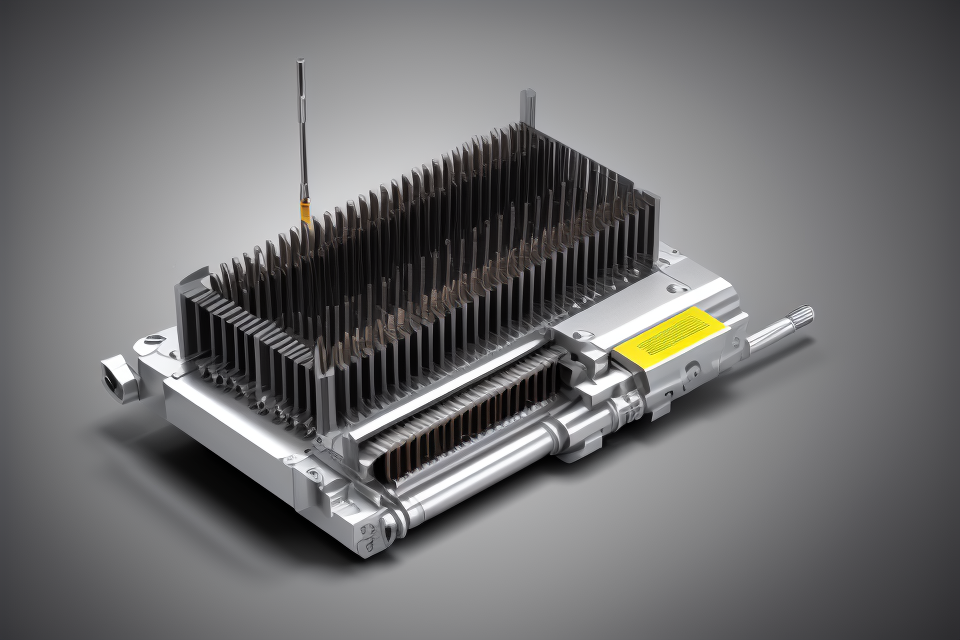

- Phase change heat sinks: These heat sinks utilize a heat-absorbing material that undergoes a phase change, such as melting or evaporation, to absorb and store heat. They are commonly used in applications where a large amount of heat needs to be dissipated, such as in power plants or industrial equipment.

- Liquid-cooled heat sinks: These heat sinks use a liquid coolant, such as water or a specialized coolant, to absorb and transport heat away from the heated component. They are commonly used in high-performance computing, data centers, and other high-power applications.

Key components of a heat sink include the base, fins, and mounting mechanism. The base is in contact with the heated component and transfers heat to the fins. The fins increase the surface area available for heat transfer, and the shape and spacing of the fins can be optimized for specific applications. The mounting mechanism secures the heat sink to the component and may also include thermal interface materials, such as thermal pads or thermal grease, to improve heat transfer between the component and the heat sink.

How Heat Sinks Work

Heat sinks are passive thermal management systems that help to dissipate heat generated by electronic components. They work by providing a large surface area for heat transfer, which facilitates the dissipation of heat into the surrounding environment. In this section, we will explore the various mechanisms by which heat sinks work to remove heat from electronic components.

Thermal management

Thermal management is the process of controlling the temperature of electronic components to ensure that they operate within their specified temperature range. Heat sinks play a critical role in thermal management by providing a large surface area for heat transfer, which helps to dissipate heat generated by electronic components. By increasing the surface area available for heat transfer, heat sinks can increase the rate at which heat is dissipated, thereby reducing the temperature of electronic components.

Heat transfer

Heat transfer is the process by which heat is transferred from one object to another. Heat sinks work by increasing the surface area available for heat transfer, which facilitates the dissipation of heat into the surrounding environment. The increased surface area provides more opportunities for heat to be transferred to the surrounding air, which helps to dissipate the heat generated by electronic components.

There are three main mechanisms by which heat transfer occurs: conduction, convection, and radiation. Conduction is the transfer of heat through direct contact between two objects. Convection is the transfer of heat through the movement of a fluid, such as air or water. Radiation is the transfer of heat through electromagnetic waves. Heat sinks work by facilitating all three mechanisms of heat transfer, thereby increasing the rate at which heat is dissipated.

Cooling efficiency

Cooling efficiency is a measure of how effectively a heat sink dissipates heat. It is typically expressed as a ratio of the amount of heat dissipated by the heat sink to the amount of heat generated by the electronic components. A higher cooling efficiency indicates that the heat sink is more effective at dissipating heat, which can help to maintain the temperature of electronic components within their specified range.

Heat sinks can be designed to optimize cooling efficiency. For example, increasing the surface area of the heat sink can increase the rate at which heat is dissipated, thereby improving cooling efficiency. Additionally, using materials with high thermal conductivity can help to improve cooling efficiency by facilitating the transfer of heat from the electronic components to the heat sink.

Overall, heat sinks play a critical role in thermal management by providing a large surface area for heat transfer, which helps to dissipate heat generated by electronic components. By optimizing cooling efficiency, heat sinks can help to maintain the temperature of electronic components within their specified range, which is essential for ensuring their reliable operation.

Heat Sink Radiation

The Science Behind Heat Sink Radiation

Blackbody Radiation

Blackbody radiation is a phenomenon in which a heated object emits electromagnetic radiation across the entire spectrum of wavelengths. The radiation is determined by the object’s temperature and follows the Planck’s law. This type of radiation occurs when an object is in thermal equilibrium with its surroundings. In the case of heat sinks, blackbody radiation plays a significant role in the heat transfer process.

Emissivity

Emissivity is a measure of an object’s ability to emit radiation compared to a perfect blackbody. It is defined as the ratio of the actual radiant power emitted by an object to that emitted by a perfect blackbody at the same temperature. The emissivity of a heat sink depends on its material composition and surface roughness. It is important to note that the emissivity of a material can vary depending on the wavelength of the radiation.

Radiative Heat Transfer

Radiative heat transfer is the process by which heat is transferred from one body to another through the emission and absorption of electromagnetic radiation. It is an important mechanism for heat transfer in heat sinks, as it allows for the dissipation of thermal energy from the heat-generating component to the surrounding environment. The rate of radiative heat transfer is determined by the difference in emissivity between the two bodies and their distance from each other.

In conclusion, the science behind heat sink radiation involves blackbody radiation, emissivity, and radiative heat transfer. These mechanisms play a crucial role in the efficient dissipation of thermal energy from heat-generating components and the maintenance of optimal operating temperatures in electronic systems.

Factors Affecting Heat Sink Radiation

When it comes to heat sink radiation, several factors play a crucial role in determining the amount of heat that is radiated from the heat sink. These factors include:

Surface Area

The surface area of a heat sink is an important factor that affects its ability to radiate heat. The larger the surface area of the heat sink, the more heat it can dissipate. This is because a larger surface area allows for more heat to be transferred to the surrounding environment through radiation. Therefore, increasing the surface area of a heat sink can significantly improve its thermal performance.

Temperature Gradient

The temperature gradient, or the difference in temperature between the heat sink and its surroundings, also affects the amount of heat that is radiated from the heat sink. The higher the temperature gradient, the more heat will be radiated from the heat sink. This is because a higher temperature gradient creates a stronger driving force for heat to flow from the heat sink to its surroundings. As a result, reducing the temperature gradient around a heat sink can help to improve its thermal performance.

Material Properties

The material properties of a heat sink also play a role in determining its ability to radiate heat. Different materials have different thermal conductivities, which affect how well they can conduct heat. Materials with high thermal conductivity, such as copper, can conduct heat more efficiently than materials with low thermal conductivity, such as aluminum. Additionally, the specific heat capacity of a material, which is the amount of heat required to raise the temperature of a unit mass of the material by one degree Celsius, also affects its ability to radiate heat. Materials with high specific heat capacity, such as iron, can absorb more heat before their temperature increases than materials with low specific heat capacity, such as plastic. Therefore, choosing the right material for a heat sink is crucial in optimizing its thermal performance.

Heat Sink Radiation vs. Convection

Convection: Air and Liquid Cooling

Convection is another method of heat transfer that is widely used in heat sink design. Convection is the movement of heat through a fluid, such as air or liquid, as a result of the fluid’s motion. There are two types of convection: natural convection and forced convection.

Natural Convection

Natural convection occurs when heat is transferred through a fluid due to the movement of the fluid itself. This movement is caused by differences in temperature and density between the fluid and its surroundings. As the fluid heats up, it expands and becomes less dense, causing it to rise. As the fluid cools, it contracts and becomes more dense, causing it to sink. This creates a circulation of the fluid that helps to transfer heat.

Forced Convection

Forced convection occurs when a fluid is moved by an external force, such as a fan or a pump. This movement also transfers heat through the fluid, but it is more controlled and directed than natural convection. Forced convection is often used in heat sink design because it allows for more precise control over the flow of heat.

Comparison with Radiation

Compared to radiation, convection is generally less efficient at transferring heat over long distances. However, it is more effective at transferring heat over short distances and in situations where there is a large temperature difference between the heat source and the heat sink. Additionally, convection can be more effective in enclosed spaces where radiation may be blocked by surfaces.

The Importance of Convection in Heat Sinks

Convection plays a crucial role in the effective removal of heat from heat sinks. It is the process by which heat is transferred through the movement of fluids, such as air or liquid, which in turn carries the heat away from the heat sink. The importance of convection in heat sinks can be understood through the following points:

- Enhancing cooling performance: Convection helps in enhancing the cooling performance of heat sinks by increasing the rate of heat transfer. This is achieved by increasing the flow rate of the fluid that comes in contact with the heat sink, which in turn increases the heat transfer coefficient. As a result, more heat is removed from the heat sink, thereby reducing its temperature.

- Managing thermal resistance: Convection also helps in managing the thermal resistance of heat sinks. Thermal resistance is the resistance offered by a material to the flow of heat through it. The higher the thermal resistance, the lesser the heat that can be transferred. By optimizing the design of heat sinks to increase the rate of convection, the thermal resistance can be reduced, thereby allowing more heat to be transferred away from the heat sink.

Overall, convection plays a vital role in the performance of heat sinks. It helps in removing heat efficiently and effectively, thereby ensuring that the temperature of the heat sink remains within safe limits. Understanding the importance of convection in heat sinks is essential for designing efficient cooling systems that can handle high heat loads.

Applications of Heat Sink Radiation

Industrial Applications

In industrial applications, heat sink radiation plays a crucial role in the efficient operation of various systems. Some of the key industrial applications of heat sink radiation are:

Power Electronics

Power electronics, such as electric vehicles, renewable energy systems, and motor drives, generate a significant amount of heat during operation. Heat sink radiation helps to dissipate this heat, ensuring that the systems operate within safe temperature limits. The use of heat sink radiation in power electronics also helps to improve the overall efficiency of these systems, reducing energy losses and increasing their lifespan.

Energy Generation

Heat sink radiation is also used in energy generation systems, such as thermal power plants and solar power plants. In these systems, heat sink radiation helps to dissipate the heat generated by the fuel or solar energy conversion process, preventing the buildup of excessive heat and reducing the risk of damage to the system. The use of heat sink radiation in energy generation systems also helps to increase their overall efficiency, improving the energy output and reducing costs.

Automotive Systems

Automotive systems, such as engines and transmissions, also generate a significant amount of heat during operation. Heat sink radiation helps to dissipate this heat, ensuring that the systems operate within safe temperature limits. The use of heat sink radiation in automotive systems also helps to improve their overall efficiency, reducing fuel consumption and emissions.

In summary, heat sink radiation plays a critical role in the efficient operation of industrial systems, including power electronics, energy generation, and automotive systems. Its ability to dissipate heat and improve system efficiency helps to ensure that these systems operate safely and effectively, reducing the risk of damage and improving their overall performance.

Consumer Electronics

In the modern era, consumer electronics have become an integral part of our daily lives. The increasing use of computers, laptops, smartphones, and other devices has led to a rise in the demand for efficient heat sinks. These small but essential components play a crucial role in maintaining the optimal temperature of electronic devices, preventing them from overheating and malfunctioning.

One of the most common applications of heat sinks in consumer electronics is in computer central processing units (CPUs) and graphics processing units (GPUs). These components generate a significant amount of heat during operation, which can lead to decreased performance and even damage to the device. By incorporating heat sinks into the design of these components, manufacturers can ensure that the heat generated is dissipated efficiently, allowing the device to run smoothly and for longer periods.

Heat sinks are also used in mobile devices such as smartphones and tablets. With the increasing power of these devices, the heat generated by their processors has become a major concern. Heat sinks help to dissipate this heat, allowing the device to run smoothly and preventing it from overheating. Additionally, heat sinks are also used in other components of these devices, such as the battery and the circuit board, to prevent overheating and extend the lifespan of the device.

Overall, the use of heat sinks in consumer electronics is crucial for maintaining the optimal temperature of these devices, ensuring their longevity and performance. As technology continues to advance, the demand for efficient heat sinks is likely to increase, making it an important area of research and development.

Designing for Efficient Heat Sink Radiation

Optimizing Heat Sink Geometry

In order to maximize the efficiency of heat sink radiation, it is essential to optimize the geometry of the heat sink. There are several key design factors that can be adjusted to improve the performance of a heat sink. These include the design of the fins, the surface texture, and the use of fins versus flat plates.

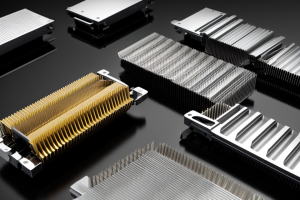

Fin Design

The design of the fins on a heat sink is a critical factor in determining its performance. Fins increase the surface area available for heat transfer, which can improve the efficiency of the heat sink. However, the size and shape of the fins can also affect the flow of air over the heat sink, which can impact its performance. For example, very large fins may create turbulence that can impede airflow, while very small fins may not provide enough surface area for effective heat transfer. The optimal fin design will depend on the specific requirements of the application.

Surface Texture

The surface texture of a heat sink can also affect its performance. A rough surface texture can increase the coefficient of friction between the heat sink and the air, which can improve heat transfer. However, a surface that is too rough can also create turbulence that can impede airflow. The optimal surface texture will depend on the specific requirements of the application.

Fins and Flat Plates

The choice between using fins or flat plates can also impact the performance of a heat sink. Fins can increase the surface area available for heat transfer, which can improve the efficiency of the heat sink. However, fins can also create resistance to airflow, which can reduce the performance of the heat sink. Flat plates have a lower resistance to airflow, but may not provide as much surface area for heat transfer as fins. The optimal choice between fins and flat plates will depend on the specific requirements of the application.

Material Selection for Heat Sinks

The material selection for heat sinks plays a crucial role in determining their efficiency in radiating heat. The following factors should be considered when selecting materials for heat sinks:

- Thermal conductivity: The thermal conductivity of a material refers to its ability to conduct heat. Materials with high thermal conductivity are more efficient at dissipating heat than those with low thermal conductivity. Common materials used for heat sinks include aluminum, copper, and silicon. Among these, copper has the highest thermal conductivity, followed by aluminum and silicon.

- Thermal expansion: Thermal expansion is the increase in size of a material due to a change in temperature. Materials with low thermal expansion coefficients are preferred for heat sinks because they are less likely to warp or crack under high temperatures. Aluminum has a lower thermal expansion coefficient than copper, making it a popular choice for heat sinks.

- Corrosion resistance: Heat sinks are often exposed to high temperatures and may come into contact with corrosive materials. Therefore, it is important to select materials that are corrosion-resistant to ensure durability and efficiency. Aluminum and copper are both corrosion-resistant materials commonly used in heat sink design.

In summary, the material selection for heat sinks should take into account the thermal conductivity, thermal expansion, and corrosion resistance of the material. Copper and aluminum are commonly used materials due to their high thermal conductivity, low thermal expansion coefficients, and corrosion resistance.

Cooling Fan Considerations

Airflow

Airflow is a critical factor in heat sink radiation design. It plays a significant role in the cooling process by moving the hot air away from the heat sink. This ensures that the heat sink does not overheat and can continue to operate efficiently. There are several key aspects of airflow that must be considered during the design process.

Firstly, the volume of airflow required will depend on the heat load of the device. This is the amount of heat that the device generates and must be dissipated. The higher the heat load, the greater the volume of airflow required.

Secondly, the direction of airflow is also important. Air should be directed over the heat sink fins to maximize the heat transfer. This can be achieved by placing the fan directly on the heat sink or by using a duct to direct the airflow.

Noise reduction

Another important consideration for cooling fans is noise reduction. High-speed fans can generate a lot of noise, which can be a major source of annoyance for users. To reduce noise levels, it is important to use fans with low noise levels or to place them in a location where they are not easily audible.

Energy efficiency

Energy efficiency is also an important consideration for cooling fans. As they are often used for extended periods of time, they can consume a significant amount of power. Therefore, it is important to use energy-efficient fans that consume less power without sacrificing performance.

Overall, cooling fan considerations are critical for efficient heat sink radiation. By considering airflow, noise reduction, and energy efficiency, designers can create heat sinks that operate effectively and quietly while consuming minimal power.

FAQs

1. What is a heat sink?

A heat sink is a passive heat dissipation device that is used to dissipate heat generated by electronic components, such as transistors and diodes. It is designed to transfer heat from the component to the surrounding environment.

2. How does a heat sink work?

A heat sink works by increasing the surface area of the component that is in contact with the surrounding air. This allows for more efficient heat transfer from the component to the air. Heat sinks can also have fins or other designs that increase the surface area and improve heat transfer.

3. Do heat sinks radiate heat?

Yes, heat sinks do radiate heat. The heat generated by the electronic component is transferred to the heat sink, and then to the surrounding air through a process called radiation. Radiation is one of the three ways that heat can be transferred, along with conduction and convection.

4. Can heat sinks cause damage to electronic components?

Heat sinks are designed to dissipate heat, not cause damage to electronic components. However, if a heat sink is not properly installed or is not in contact with the component, it may actually cause the component to overheat and be damaged. It is important to follow the manufacturer’s instructions when installing a heat sink.

5. Are heat sinks necessary for all electronic components?

Not all electronic components require a heat sink. Some components, such as resistors and capacitors, do not generate enough heat to require a heat sink. However, components such as transistors and diodes can generate a significant amount of heat and require a heat sink to prevent overheating and damage.

6. Can heat sinks be used with any type of electronic component?

Heat sinks are designed to work with specific types of electronic components. It is important to choose a heat sink that is compatible with the specific component that you are using. Using the wrong type of heat sink can actually cause damage to the component.

7. How do I know if my electronic component needs a heat sink?

If your electronic component generates a significant amount of heat, it may require a heat sink. Signs that a heat sink may be necessary include the component running hot to the touch, thermal throttling, or the component failing due to overheating. It is always a good idea to consult the manufacturer’s specifications for your specific component to determine if a heat sink is necessary.