Are you looking to keep your electronic devices cool and running smoothly? If so, you may be considering a liquid cooler. But where is the best place to put it? The answer to this question can make a big difference in the efficiency and performance of your liquid cooler. In this article, we will explore the optimal placement for liquid coolers and provide tips on how to maximize their effectiveness. So, whether you’re a seasoned pro or a newcomer to liquid cooling, read on to discover the secrets to keeping your devices cool and running at peak performance.

Factors Affecting Liquid Cooler Placement

System Design and Configuration

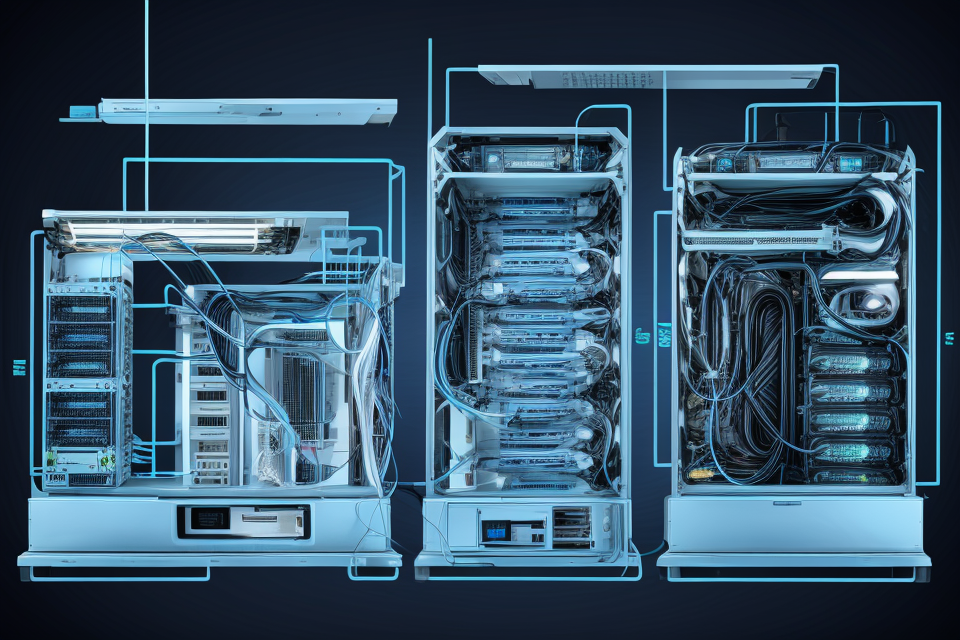

The design and configuration of a computer system play a crucial role in determining the optimal placement of liquid coolers. A well-designed system ensures efficient heat dissipation and prevents potential issues that may arise from poor placement. Here are some key factors to consider when designing a system for optimal liquid cooler placement:

Dual-loop or single-loop configuration

One of the primary considerations when designing a system for liquid cooling is whether to use a dual-loop or single-loop configuration. A dual-loop configuration involves two separate loops, one for the CPU and another for the GPU or other components. This setup offers greater flexibility and can provide more efficient cooling for high-performance components. In contrast, a single-loop configuration utilizes a single loop to cool all components. While it is less complex, it may not be as effective in cooling high-performance components.

Component layout and arrangement

The layout and arrangement of components within the system also impact the optimal placement of liquid coolers. Ideally, components that generate the most heat should be placed closest to the liquid cooler. For example, the CPU is typically the most critical component in terms of heat dissipation and should be placed near the liquid cooler. Other high-performance components, such as GPUs or CPUs with overclocked cores, should also be placed in close proximity to the liquid cooler.

Clearance and compatibility issues

When designing a system for optimal liquid cooler placement, it is essential to consider clearance and compatibility issues. The size and shape of the liquid cooler must fit within the available space in the system. Additionally, the liquid cooler must be compatible with the components it is cooling. For example, some liquid coolers may not be compatible with certain CPU sockets or may require specific mounting hardware.

In summary, the design and configuration of a computer system play a critical role in determining the optimal placement of liquid coolers. By considering factors such as dual-loop or single-loop configuration, component layout and arrangement, and clearance and compatibility issues, system builders can ensure efficient heat dissipation and maximize the performance of their liquid cooling systems.

Heat Dissipation and Transfer

Effective heat dissipation and transfer are crucial factors to consider when determining the optimal placement of liquid coolers. There are several elements that contribute to this process, including airflow and ventilation, heat exchanger placement, and cold plate orientation.

- Airflow and Ventilation: The flow of air around the liquid cooler plays a significant role in dissipating heat. It is important to ensure that there is adequate airflow and ventilation around the cooler to facilitate heat transfer. Obstructions or restrictions in the airflow can negatively impact the cooler’s performance, resulting in decreased efficiency and potential damage to the system.

- Heat Exchanger Placement: The placement of the heat exchanger within the liquid cooler is a critical factor in determining its heat dissipation capabilities. The heat exchanger should be placed in a location where it can efficiently transfer heat to the surrounding air. In some cases, this may involve orienting the heat exchanger in a specific direction to maximize airflow and increase the rate of heat transfer.

- Cold Plate Orientation: The orientation of the cold plate, which contains the liquid coolant, also impacts the cooler’s heat dissipation capabilities. The cold plate should be positioned in a way that allows for optimal circulation of the coolant, enabling it to efficiently absorb heat from the components being cooled. The orientation of the cold plate may also affect the flow of air around the cooler, and should be considered in conjunction with the placement of the heat exchanger.

In summary, optimal placement of liquid coolers involves carefully considering factors such as airflow and ventilation, heat exchanger placement, and cold plate orientation to ensure efficient heat dissipation and transfer. Proper placement can significantly enhance the performance and lifespan of the liquid cooler, ultimately leading to improved overall system efficiency.

Liquid Flow and Distribution

- Radiator location and orientation

- Filling and topping off

- Tubing and fitting management

Radiator Location and Orientation

The positioning of a radiator plays a crucial role in determining the effectiveness of a liquid cooling system. Ideally, the radiator should be placed in a location where it can receive the maximum amount of airflow without being obstructed by other components. The orientation of the radiator is also important, as it should be placed in a way that allows the air to flow through it evenly.

Filling and Topping Off

Ensuring that the liquid cooling system is properly filled and topped off is essential for maintaining optimal performance. When filling the system, it is important to use the correct type and amount of coolant. The coolant should be added slowly and carefully to prevent air pockets from forming, which can cause problems with the circulation of the liquid.

Tubing and Fitting Management

The tubing and fittings used in a liquid cooling system must be managed carefully to ensure that they are installed correctly and do not impede the flow of liquid. The tubing should be routed in a way that allows the liquid to flow smoothly through the system, without any kinks or restrictions. The fittings should be secured tightly to prevent leaks, but not so tightly that they restrict the flow of liquid.

Overall, optimizing the placement of liquid coolers requires careful consideration of the factors that affect liquid flow and distribution. By taking the time to properly position the radiator, fill the system, and manage the tubing and fittings, it is possible to maximize the efficiency and performance of a liquid cooling system.

Choosing the Best Location for Your Liquid Cooler

Methods for Evaluating Cooling Performance

Temperature Monitoring and Readings

One method for evaluating the cooling performance of a liquid cooler is to monitor and record the temperature of the system components before and after installation. This can be done using temperature sensors or probes placed at strategic locations within the system. By comparing the temperatures before and after installation, it is possible to determine the effectiveness of the liquid cooler in reducing the overall temperature of the system.

Pressure Drop Measurement

Another method for evaluating the cooling performance of a liquid cooler is to measure the pressure drop across the system. This can be done using a pressure gauge or transducer connected to the liquid cooler. By measuring the pressure drop, it is possible to determine the amount of heat that is being transferred from the system components to the liquid cooler. This information can be used to calculate the thermal resistance of the liquid cooler and compare it to the thermal resistance of other components in the system.

Flow Rate Assessment

Finally, the flow rate of the liquid cooler can also be assessed to evaluate its cooling performance. This can be done by measuring the volume of liquid that is pumped through the system per unit of time. By comparing the flow rate of the liquid cooler to the flow rate of other components in the system, it is possible to determine the effectiveness of the liquid cooler in moving heat away from the system components. This information can be used to optimize the placement of the liquid cooler for maximum efficiency and performance.

Guidelines for Optimal Placement

Proper placement of liquid coolers is crucial in maximizing their efficiency and performance. The following guidelines should be considered when choosing the best location for your liquid cooler:

- Aligning components for maximum heat transfer

- Ensuring adequate airflow and cooling capacity

- Balancing pressure drop and flow rate

Aligning Components for Maximum Heat Transfer

To achieve maximum heat transfer, it is important to align the liquid cooler with the hottest components in the system. This ensures that the cooler can efficiently dissipate heat from the components and maintain optimal operating temperatures. The alignment should be done in such a way that the liquid cooler is in close contact with the components, allowing for efficient heat transfer.

Ensuring Adequate Airflow and Cooling Capacity

Adequate airflow is essential for the efficient operation of liquid coolers. The cooler should be placed in a location that allows for sufficient airflow around the components to be cooled. This is important because the cooler relies on the airflow to dissipate the heat generated by the components. Therefore, the location of the liquid cooler should be chosen to ensure that there is enough airflow to cool the components effectively.

Balancing Pressure Drop and Flow Rate

The pressure drop across the liquid cooler should be balanced with the flow rate to ensure efficient heat transfer. The pressure drop is the decrease in pressure of the liquid as it flows through the cooler. This pressure drop should be kept within the recommended range for the specific cooler to ensure that the liquid flows at the required rate for efficient heat transfer. On the other hand, the flow rate should be sufficient to remove the heat generated by the components effectively. Therefore, the location of the liquid cooler should be chosen to balance the pressure drop and flow rate for optimal performance.

Implementing and Adjusting Liquid Cooler Placement

Preparing the System for Installation

Cleaning and Disinfecting Components

Before installing a liquid cooler, it is essential to clean and disinfect all components that will come into contact with the cooling liquid. This includes the water block, tubing, fittings, and reservoir.

To clean the components, use a mild detergent and warm water. Dismantle the water block and clean the internal channels thoroughly. Ensure that all surfaces are free from debris, dust, and other contaminants.

After cleaning, disinfect all components using an appropriate disinfectant. This will help prevent the growth of bacteria and other microorganisms that can clog the system and reduce its efficiency.

Assembling and Connecting Parts

Once the components are clean and disinfected, it’s time to assemble the liquid cooler. Begin by attaching the water block to the CPU or other components that need cooling. Make sure the water block is securely fastened and that the fittings are tight.

Next, connect the tubing to the water block and the reservoir. Ensure that the tubing is inserted into the correct ports and that there are no kinks or blockages. Finally, connect the reservoir to the pump, ensuring that the connections are secure.

Flushing and Priming the Cooling System

After assembling the liquid cooler, it’s crucial to flush and prime the cooling system. Flushing the system removes any air pockets or debris that may have accumulated during assembly. To flush the system, attach a tubing filled with liquid to the reservoir and slowly pour in a flushing solution. Continue flushing until the liquid coming out of the tubing is clear.

Once the system is flushed, it’s time to prime it. To prime the system, attach a tubing filled with liquid to the reservoir and slowly pour in a priming solution. Continue priming until the liquid coming out of the tubing is clear and there are no air pockets in the system.

By following these steps, you can prepare your system for the installation of a liquid cooler, ensuring optimal efficiency and performance.

Monitoring and Fine-tuning the Cooling Performance

In order to ensure that the liquid cooler is performing optimally, it is essential to monitor and fine-tune its cooling performance regularly. This can be achieved through continuous temperature and pressure monitoring, adjusting fan speed and control settings, and revising fluid levels and coolant mixtures.

Continuous Temperature and Pressure Monitoring

One of the key aspects of monitoring and fine-tuning the cooling performance of a liquid cooler is to continuously monitor its temperature and pressure levels. This can be done using specialized sensors that measure the temperature and pressure of the coolant as it flows through the system. By tracking these values over time, it is possible to identify any potential issues or inefficiencies in the cooling system and take corrective action as needed.

Adjusting Fan Speed and Control Settings

Another important aspect of monitoring and fine-tuning the cooling performance of a liquid cooler is to adjust its fan speed and control settings. The fan is responsible for circulating the coolant throughout the system and removing any heat that has been generated. By adjusting the fan speed and control settings, it is possible to optimize the cooling performance of the liquid cooler and ensure that it is operating at maximum efficiency.

Revising Fluid Levels and Coolant Mixtures

Finally, it is also important to regularly revise the fluid levels and coolant mixtures in the liquid cooler. Over time, the coolant may become contaminated or depleted, which can negatively impact the cooling performance of the system. By regularly checking the fluid levels and coolant mixtures, it is possible to ensure that the liquid cooler is operating at maximum efficiency and to make any necessary adjustments to maintain optimal performance.

In summary, monitoring and fine-tuning the cooling performance of a liquid cooler is essential for ensuring that it is operating at maximum efficiency and performance. By continuously monitoring temperature and pressure levels, adjusting fan speed and control settings, and revising fluid levels and coolant mixtures, it is possible to optimize the cooling performance of the liquid cooler and achieve the best possible results.

Maximizing the Benefits of Liquid Cooling Systems

Efficient Thermal Management

Liquid cooling systems offer several advantages over traditional air cooling systems. One of the most significant benefits is efficient thermal management. This is achieved by placing the liquid cooler in the optimal location to maximize cooling performance and stability while minimizing noise and heat emissions.

Enhanced Cooling Performance and Stability

Liquid cooling systems use a liquid coolant to transfer heat away from the components, which allows for more efficient cooling compared to air cooling systems. The liquid coolant can absorb more heat before it reaches its boiling point, which means it can transfer more heat over a longer distance. This results in a more stable temperature throughout the system, which can improve the performance and lifespan of the components.

Minimized Noise and Heat Emissions

Liquid cooling systems are also quieter than air cooling systems because the liquid coolant does not require fans to move it through the system. This means that there is less noise generated by the cooling system, which can improve the overall user experience. Additionally, liquid cooling systems can be designed to recirculate the coolant, which reduces the amount of heat emitted by the system.

Extended Component Lifespan and Reliability

The efficient thermal management provided by liquid cooling systems can also help to extend the lifespan and reliability of the components. By maintaining a stable temperature throughout the system, the components are less likely to experience thermal stress, which can cause damage over time. Additionally, the liquid coolant can be designed to include additives that can help to protect the components from corrosion and other forms of damage.

Overall, the efficient thermal management provided by liquid cooling systems can help to improve the performance and reliability of the system while minimizing noise and heat emissions. By placing the liquid cooler in the optimal location, it is possible to maximize these benefits and achieve the best possible results.

Scalability and Customization

One of the primary advantages of liquid cooling systems is their scalability and customization capabilities. These features enable users to adapt the system to their specific needs, making it an ideal solution for various applications. Here are some of the benefits of scalability and customization in liquid cooling systems:

Flexible system design and expansion

Liquid cooling systems can be designed to accommodate different sizes and configurations of components. This flexibility allows users to expand their systems as needed, without having to replace the entire cooling solution. The modular design of liquid coolers enables users to add or remove components based on the current requirements, ensuring optimal performance at all times.

Adapting to varying cooling demands

Different components in a system may have varying cooling demands, and liquid cooling systems can be tailored to meet these requirements. By adjusting the flow rate, temperature, and pressure of the coolant, users can ensure that each component receives the appropriate amount of cooling. This adaptability is particularly beneficial for high-performance applications, such as gaming PCs and data centers, where cooling demands can fluctuate rapidly.

Personalized aesthetics and styling options

Liquid cooling systems offer a range of customization options for users who want to enhance the visual appeal of their PCs. The transparent tubing used in these systems allows users to showcase the coolant flow and the components it contacts. Customers can choose from a variety of colors and materials for the tubing, as well as add additional lighting or design elements to create a unique and visually appealing setup. This level of customization is particularly appealing to enthusiasts who value both performance and aesthetics in their PC builds.

FAQs

1. What is a liquid cooler?

A liquid cooler, also known as a liquid-to-air cooler or all-in-one cooler, is a type of CPU cooler that uses liquid coolant to dissipate heat generated by the CPU. The liquid coolant is pumped through a copper or plastic radiator, which has fans mounted on it to dissipate the heat. Liquid coolers are popular among PC builders because they can provide better cooling performance than traditional air coolers.

2. Why is the placement of a liquid cooler important?

The placement of a liquid cooler is important because it can affect the cooler’s ability to dissipate heat. If the cooler is not placed in an optimal location, it may not be able to efficiently remove heat from the CPU, which can lead to reduced performance and even damage to the CPU.

3. What are the best locations for a liquid cooler?

The best location for a liquid cooler is typically in the front or top of the case, where the cooler can benefit from the best airflow. However, the exact location will depend on the specific case and components in the build. In general, it’s important to ensure that the cooler is not obstructed by other components or fans, and that there is enough clearance for the radiator and fans to function properly.

4. Can I put a liquid cooler in any location in my case?

It’s generally not recommended to place a liquid cooler in any location in your case, as it may not provide optimal cooling performance or may interfere with other components. Before installing a liquid cooler, it’s important to carefully consider the layout of your case and the location of other components to ensure that the cooler is placed in the best possible location.

5. How do I know if a location is suitable for a liquid cooler?

To determine if a location is suitable for a liquid cooler, you should consider several factors, including airflow, clearance, and proximity to other components. Ideally, the location should provide good airflow from front to back and side to side, and should not be obstructed by other components or fans. Additionally, there should be enough clearance for the radiator and fans to function properly, and the location should not be too close to other components that could interfere with the cooler’s operation.

6. What are the potential risks of placing a liquid cooler in a suboptimal location?

The potential risks of placing a liquid cooler in a suboptimal location include reduced cooling performance, increased noise levels, and damage to the CPU or other components. If the cooler is not able to efficiently remove heat from the CPU, it may cause the CPU to overheat, which can lead to reduced performance and even damage to the CPU. Additionally, if the cooler is obstructed or interferes with other components, it may increase noise levels and reduce the overall performance of the system.

7. How can I ensure optimal placement of a liquid cooler?

To ensure optimal placement of a liquid cooler, you should carefully consider the layout of your case and the location of other components. You should also take into account the size and orientation of the radiator and fans, as well as the type of liquid coolant being used. Additionally, you should make sure that there is enough clearance for the radiator and fans to function properly, and that the location is not obstructed by other components or fans.