A heat sink is a component used to dissipate heat from electronic devices. While it is essential for regulating the temperature of devices, it also has its drawbacks. In this article, we will explore the disadvantages of using a heat sink. From increased size and weight to decreased efficiency, we will cover all the factors that make heat sinks a less than ideal solution in certain situations. Whether you’re a DIY enthusiast or a professional engineer, understanding the limitations of heat sinks is crucial for making informed decisions when it comes to thermal management. So, let’s dive in and explore the downsides of using a heat sink.

The drawbacks of using a heat sink include increased cost, weight, and complexity, as well as potential thermal resistance and reduced thermal conductivity. Additionally, heat sinks can be prone to damage from vibration and can require careful placement to ensure proper heat dissipation. Finally, heat sinks may not be effective in all situations, particularly in cases where there is limited space for airflow or when the heat source is not well-distributed. Overall, while heat sinks can be an effective solution for managing heat in some applications, they are not without their drawbacks and should be carefully considered in terms of their cost, performance, and practicality.

Understanding Heat Sinks

What is a Heat Sink?

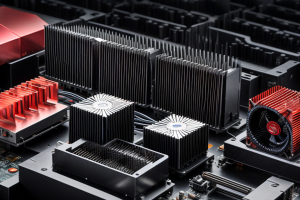

A heat sink is a passive device used to transfer heat from one object to another. It is typically used to dissipate excess heat generated by electronic components, such as processors and power semiconductors, to ensure their safe operation and prolong their lifespan. A heat sink consists of a metal container or plate with a large surface area, which is in contact with the component to be cooled. The heat sink also includes one or more fins or channels to increase its surface area and improve heat transfer. The fins or channels may be designed to enhance convection, conduction, or radiation heat transfer mechanisms, depending on the application.

In operation, the heat generated by the electronic component is transferred to the metal container or plate of the heat sink. The heat then flows through the metal and into the fins or channels, where it is dissipated into the surrounding environment by natural convection, forced air flow, or other cooling methods. The heat sink helps to maintain the temperature of the electronic component within safe operating limits, preventing overheating and thermal damage.

Types of Heat Sinks

There are several types of heat sinks available, each with its own advantages and disadvantages. Some of the most common types of heat sinks include:

Air-Cooled Heat Sinks

Air-cooled heat sinks are the most commonly used type of heat sink. They consist of a metal plate or fin that is designed to dissipate heat through convection, which is the transfer of heat through the movement of air. Air-cooled heat sinks are relatively simple and easy to install, and they are also relatively inexpensive. However, they can be less efficient than other types of heat sinks, particularly in applications where the ambient temperature is high or the airflow is limited.

Liquid-Cooled Heat Sinks

Liquid-cooled heat sinks use a liquid coolant to transfer heat away from the heat-generating component. This type of heat sink is commonly used in high-performance computing applications, such as servers and data centers. Liquid-cooled heat sinks are highly efficient and can dissipate large amounts of heat. However, they can be more complex and expensive to install than air-cooled heat sinks.

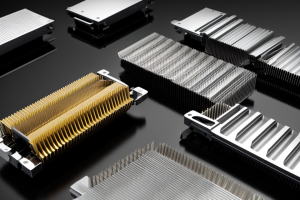

Extruded Heat Sinks

Extruded heat sinks are made by extruding a heatsink base material through a die to form a specific shape. They are often used in applications where a large amount of heat needs to be dissipated quickly, such as in power electronics and automotive applications. Extruded heat sinks are highly efficient and can be made from a variety of materials, including aluminum and copper. However, they can be more expensive than other types of heat sinks and may require additional components, such as fans or radiators, to be effective.

Disadvantages of Heat Sinks

Weight and Size

Using a heat sink can have its drawbacks, especially when it comes to weight and size. While a heat sink is designed to dissipate heat and prevent overheating, it can also add significant weight and size to a system.

- Increased Weight: One of the primary drawbacks of using a heat sink is the increased weight it adds to a system. This can make the system heavier and more difficult to move or transport. Depending on the size and number of heat sinks used, the weight increase can be significant. This can also affect the overall performance of the system, as a heavier system may require more power to operate, leading to reduced efficiency and increased energy costs.

- Large Size: Another disadvantage of using a heat sink is its large size. Heat sinks can take up a significant amount of space, which can limit the size and shape of the system. This can be especially problematic in applications where space is limited, such as in portable devices or small appliances. Additionally, the large size of a heat sink can make it more difficult to install or replace, which can lead to additional costs and downtime.

Overall, the weight and size of a heat sink can have a significant impact on the performance and functionality of a system. While heat sinks are essential for preventing overheating and ensuring optimal performance, it is important to carefully consider their weight and size when designing a system to ensure that they do not negatively impact the system’s overall performance.

Cost

One of the main drawbacks of using a heat sink is the cost associated with it. Heat sinks can be quite expensive, especially when purchased in large quantities. Additionally, installation costs can also add up, as the heat sink needs to be properly mounted and connected to the system.

The cost of a heat sink can vary depending on its size, material, and design. Some heat sinks are made of high-quality materials, such as copper or aluminum, which can increase the overall cost. Additionally, the size of the heat sink can also impact its cost, as larger heat sinks are typically more expensive than smaller ones.

In addition to the initial purchase cost, installation costs can also add up. The heat sink needs to be properly mounted and connected to the system, which can require specialized tools and expertise. In some cases, the installation process can be time-consuming and may require multiple technicians.

Another factor to consider is the potential for ongoing maintenance costs. Heat sinks can be prone to damage, especially in high-temperature environments. If the heat sink becomes damaged, it may need to be repaired or replaced, which can add up over time.

Overall, the cost of using a heat sink can be significant, and it is important to weigh the benefits against the costs before deciding to use one. It is also important to consider the potential for ongoing maintenance costs and ensure that the heat sink is properly maintained to avoid costly repairs or replacements in the future.

Maintenance

When it comes to using a heat sink, one of the main drawbacks is the maintenance required to keep it functioning properly. Here are some of the key disadvantages of heat sink maintenance:

- Difficult to Maintain: Heat sinks can be difficult to maintain, especially if they are located in hard-to-reach places. This can make it challenging to clean the heat sink and ensure that it is functioning properly.

- Requires Regular Cleaning: In order to maintain the efficiency of a heat sink, it is important to clean it regularly. This is because dust and other debris can accumulate on the heat sink, which can impede its ability to dissipate heat. If the heat sink is not cleaned regularly, it may become less effective over time.

Additionally, heat sinks can be sensitive to damage from vibration and physical impact, which can also make maintenance more challenging. Overall, the maintenance requirements of a heat sink can be a significant drawback, especially for those who are not experienced with heat sink maintenance.

Efficiency

One of the primary disadvantages of using a heat sink is that its efficiency is dependent on the ambient temperature. In other words, the heat sink’s ability to dissipate heat is directly proportional to the difference between the ambient temperature and the temperature of the component being cooled. Therefore, if the ambient temperature is already close to the temperature of the component, the heat sink’s efficiency will be significantly reduced.

Moreover, using a heat sink can actually reduce the overall efficiency of the system. This is because the heat sink itself generates resistance, which in turn generates heat. This additional heat can then further increase the temperature of the component being cooled, which can cause the heat sink to become less effective. This can create a vicious cycle where the heat sink’s efficiency is constantly reduced, leading to decreased overall system efficiency.

In addition, the size and weight of a heat sink can also affect its efficiency. Larger heat sinks have a greater surface area, which allows them to dissipate more heat. However, they can also be more difficult to install and may require more space, which can be a limitation in some applications. On the other hand, smaller heat sinks may be easier to install and require less space, but they may not be as effective at dissipating heat. Therefore, finding the optimal size and weight of a heat sink can be a challenge.

Noise

Using a heat sink can generate noise during its operation. This noise can be caused by various factors such as the movement of air through the heat sink, the vibration of the heat sink itself, or the sound of the fans used to cool the heat sink.

Can Generate Noise

The primary source of noise when using a heat sink is the movement of air through the heat sink. As the hot air is forced through the heat sink, it can create a whirring or humming sound. This noise can be amplified if the heat sink is located in a confined space, such as a computer case.

Can Cause Vibrations

In addition to generating noise, a heat sink can also cause vibrations. This can be due to the movement of air through the heat sink, which can create pressure changes that cause the heat sink to vibrate. Additionally, the fans used to cool the heat sink can also cause vibrations, which can be transmitted through the heat sink and into the surrounding components.

These vibrations can cause a variety of issues, including reduced lifespan of components, loosening of screws and bolts, and even damage to the heat sink itself. Therefore, it is important to properly mount and secure the heat sink to minimize the risk of vibrations.

Reliability

While heat sinks can be an effective solution for dissipating heat from electronic components, they also have some potential drawbacks in terms of reliability. Here are some of the reasons why heat sinks can be prone to failure and can be difficult to repair:

- Mechanical failure: Heat sinks are typically made of metal, which can be susceptible to mechanical failure if the device is subjected to vibration or shock. For example, if the device is mounted on a vehicle or subjected to rough handling, the heat sink can become loose or even detach from the device.

- Thermal stress: Heat sinks are designed to dissipate heat from the device, but they can also be subjected to thermal stress if the temperature differential between the heat sink and the surrounding environment is too great. This can cause the heat sink to warp or even crack, which can lead to failure.

- Corrosion: Heat sinks that are exposed to moisture or other corrosive substances can be prone to corrosion, which can cause them to fail over time. This is particularly true for heat sinks that are used in harsh environments, such as outdoors or in industrial settings.

- Complexity: Heat sinks can be complex to design and manufacture, and errors in the design or manufacturing process can lead to failure. For example, if the heat sink is not properly aligned with the device, it may not be able to dissipate heat effectively, leading to failure.

Overall, while heat sinks can be an effective solution for dissipating heat from electronic components, they also have some potential drawbacks in terms of reliability. It is important to carefully consider the specific requirements of the device and the environment in which it will be used to ensure that the heat sink is designed and installed properly to avoid failure.

Compatibility

While heat sinks are designed to dissipate heat effectively, they may not be compatible with all systems. This can pose a significant problem for users who require a heat sink that fits their specific system requirements. In some cases, the heat sink may not fit the system’s dimensions or shape, making it difficult to install. In other cases, the heat sink may not have the necessary connectors or interfaces to attach to the system.

Furthermore, customization of heat sinks may be required to ensure compatibility with a particular system. This can be time-consuming and costly, as customization typically involves the design and manufacture of a new heat sink that meets the specific requirements of the system. Additionally, custom heat sinks may not be readily available, which can lead to delays in the production process.

In some cases, the compatibility issues with heat sinks can be mitigated by using adaptors or converters. However, these solutions may not be feasible in all situations, and may also introduce additional costs and complexity to the system. Overall, the compatibility issues associated with heat sinks can be a significant drawback for users who require a heat sink that fits their specific system requirements.

FAQs

1. What is a heat sink?

A heat sink is a passive cooling component that is used to dissipate heat generated by electronic components. It is usually made of metal and has a large surface area to increase the heat transfer rate from the component to the surrounding air.

2. What are the advantages of using a heat sink?

The main advantage of using a heat sink is that it helps to keep electronic components cool, which can prevent them from overheating and failing. This can extend the lifespan of the component and improve its performance. Heat sinks can also be used to improve the thermal performance of a system by allowing for better heat dissipation.

3. What are the disadvantages of using a heat sink?

One disadvantage of using a heat sink is that it can add weight and size to a system, which can make it more difficult to install and maintain. Heat sinks can also be expensive to manufacture and purchase, which can make them less accessible to some users. Additionally, heat sinks can be prone to thermal resistance, which can reduce their effectiveness and cause them to overheat.

4. Can a heat sink cause damage to electronic components?

If a heat sink is not installed properly or if it becomes loose or damaged, it can cause damage to electronic components. This is because the heat sink can become a conductor for electricity, which can cause short circuits or other types of damage. It is important to ensure that a heat sink is installed correctly and is in good condition to prevent this type of damage from occurring.

5. How do I know if a heat sink is needed for my electronic components?

If your electronic components are generating a significant amount of heat, it may be necessary to use a heat sink to dissipate that heat. You can measure the temperature of your components using a thermometer or other temperature measurement tool to determine if a heat sink is needed. You can also consult the manufacturer’s specifications for your components to see if they recommend the use of a heat sink.