A heat sink is a device used to dissipate heat generated by electronic components. It is commonly used in various applications such as computers, automobiles, and industrial machinery. A heat sink works by transferring heat from the component to the surrounding air. The heat sink is made of materials with high thermal conductivity such as copper or aluminum. The size and design of the heat sink depend on the amount of heat that needs to be dissipated.

Advantages:

One of the main advantages of using a heat sink is that it helps to prevent overheating of electronic components. This is crucial in ensuring the proper functioning of the equipment and prolonging its lifespan. Additionally, heat sinks are relatively easy to install and require minimal maintenance. They are also lightweight and compact, making them easy to integrate into various applications.

Disadvantages:

Despite its many advantages, a heat sink also has some disadvantages. One of the main drawbacks is that it can be quite expensive, especially for larger applications. Additionally, heat sinks can be quite loud, which can be a problem in quiet environments. They can also be susceptible to damage from vibration or physical impact, which can reduce their effectiveness.

In conclusion, a heat sink is a crucial component in many electronic applications. While it has several advantages, it is important to consider its disadvantages as well when deciding whether to use one.

Heat sinks are commonly used in electronic devices to dissipate excess heat generated by the components. The advantages of using a heat sink include increased reliability and longer lifespan of the components, improved performance and efficiency of the device, and better thermal management. However, there are also some disadvantages to using a heat sink, such as increased size and weight, additional cost, and complexity of the design. Additionally, if the heat sink is not properly designed or installed, it can actually cause more heat buildup and damage to the components. Therefore, it is important to carefully consider the specific requirements and limitations of the device and application before deciding to use a heat sink.

What is a Heat Sink?

Definition and Function

A heat sink is a passive thermal management component designed to dissipate heat generated by electronic devices. It increases the surface area available for heat transfer, facilitating the transfer of heat from the source to the surrounding environment.

In simpler terms, a heat sink is a metal object that is placed in close contact with an electronic component to dissipate excess heat. It is an essential component in devices that generate significant amounts of heat, such as computers, servers, and power electronics.

The primary function of a heat sink is to lower the temperature of the electronic component it is in contact with. It does this by increasing the surface area available for heat transfer, thus allowing the heat to dissipate more quickly. This helps to prevent overheating, which can damage the electronic component and reduce its lifespan.

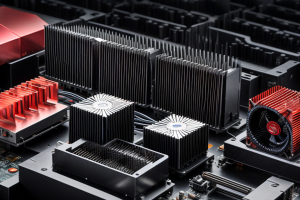

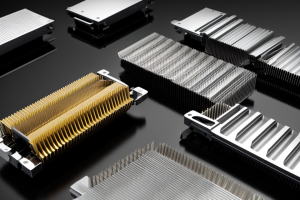

Heat sinks come in various shapes and sizes, and they can be made from different materials, including aluminum, copper, and steel. The choice of material depends on the specific application and the required thermal performance.

In summary, a heat sink is a crucial component in thermal management systems, designed to help electronic devices maintain safe operating temperatures by dissipating excess heat.

Types of Heat Sinks

There are several types of heat sinks, each with its own unique advantages and disadvantages. The following are the four main types of heat sinks:

- Air-cooled heat sinks: These heat sinks use air to dissipate heat from a component. They are typically used in situations where liquid cooling is not practical or desirable. Air-cooled heat sinks can be effective in certain situations, but they are not as efficient as liquid-cooled heat sinks.

- Liquid-cooled heat sinks: These heat sinks use a liquid coolant to dissipate heat from a component. They are typically used in situations where a high level of cooling is required, such as in high-performance computers and data centers. Liquid-cooled heat sinks are generally more efficient than air-cooled heat sinks, but they can be more complex to install and maintain.

- Phase-change heat sinks: These heat sinks use a phase change material (PCM) to store and release heat. PCMs can absorb and release heat as they change phase, from solid to liquid or vice versa. Phase-change heat sinks are often used in applications where a high level of thermal storage is required, such as in solar power systems.

- Vapor-compression heat sinks: These heat sinks use a vapor-compression cycle to dissipate heat from a component. They are typically used in situations where a very high level of cooling is required, such as in industrial processes or nuclear power plants. Vapor-compression heat sinks are very efficient, but they can be complex and expensive to install and maintain.

Advantages of Using a Heat Sink

Improved Thermal Performance

When it comes to electronic devices, overheating can be a major concern. The use of a heat sink can greatly improve the thermal performance of a device, allowing it to maintain safe operating temperatures.

A heat sink works by increasing the surface area available for heat dissipation. By increasing the surface area, the heat sink can effectively dissipate heat away from the device, preventing overheating and damage to sensitive components. This is particularly important in devices where a high level of power is generated, such as in computer processors and power amplifiers.

Additionally, a heat sink can also help to reduce the operating temperature of a device. This is because the heat sink allows for the transfer of heat from the device to the surrounding environment, thereby reducing the temperature of the device. This can help to extend the lifespan of the device, as well as improve its overall performance.

In summary, the use of a heat sink can greatly improve the thermal performance of a device. By increasing the surface area available for heat dissipation and allowing for the transfer of heat to the surrounding environment, a heat sink can help to prevent overheating and damage to sensitive components, as well as reduce the operating temperature of the device.

Cost-Effective

A heat sink is a cost-effective solution for managing heat in electronic devices. When compared to other cooling methods, such as active cooling systems like fans and blowers, heat sinks are relatively inexpensive.

Here are some of the reasons why heat sinks are cost-effective:

- Passive Cooling: Heat sinks are passive cooling solutions that do not require any external power source. They rely on natural convection and radiation to dissipate heat from the electronic components. This makes them a low-cost solution for cooling electronic devices.

- Simple Design: Heat sinks have a simple design that is easy to manufacture and install. They can be made from inexpensive materials like aluminum or copper, and they can be designed to fit a wide range of electronic devices. This simplicity makes them a cost-effective solution for managing heat in electronic devices.

- Longevity: Heat sinks are designed to last for a long time. They are made from durable materials that can withstand high temperatures and are resistant to corrosion. This means that they do not need to be replaced frequently, which makes them a cost-effective solution in the long run.

- Efficient: Heat sinks are highly efficient at dissipating heat from electronic components. They can transfer heat up to 10 times faster than air, which makes them an effective solution for managing heat in electronic devices. This efficiency means that they can help to extend the lifespan of electronic components, which can save money in the long run.

Overall, heat sinks are a cost-effective solution for managing heat in electronic devices. They are simple, efficient, and durable, which makes them a low-cost solution for cooling electronic devices.

Quiet Operation

One of the key advantages of using a heat sink is its quiet operation. Heat sinks are designed to dissipate heat efficiently and effectively, without producing any noise. This makes them ideal for applications where noise levels need to be minimized, such as data centers and server rooms.

In a data center, hundreds or even thousands of servers are often operated in close proximity to each other. Any noise generated by the servers can quickly add up and become a major distraction. By using heat sinks, the noise levels can be reduced significantly, making the environment more comfortable for workers and reducing the risk of complaints from neighbors.

In addition to reducing noise levels, heat sinks also help to reduce the risk of equipment failure. When servers and other electronic components become too hot, they can overheat and fail, leading to costly downtime and repairs. By using a heat sink, the risk of overheating is reduced, helping to extend the lifespan of the equipment and reduce the need for repairs.

Another advantage of using a heat sink is that it can be easily customized to meet the specific needs of an application. Heat sinks come in a wide range of sizes and configurations, allowing them to be tailored to the specific requirements of a particular application. This makes them highly versatile and adaptable, making them an ideal choice for a wide range of applications.

Increased Lifespan of Electronic Devices

Electronic devices generate heat during operation, which can cause damage to the components and lead to premature failure. A heat sink is a passive cooling device that helps to dissipate the excess heat generated by the device, preventing it from reaching critical temperatures that could cause failure. By using a heat sink, electronic devices can operate within their recommended temperature range, leading to longer lifespan and better performance.

In fact, studies have shown that the use of heat sinks can increase the lifespan of electronic devices by up to 30%. This is because the heat sink helps to remove the heat generated by the device, which can cause damage to the components over time. By keeping the device cool, the heat sink can prevent premature failure due to overheating, leading to a longer lifespan for the device.

Additionally, heat sinks can also improve the performance of electronic devices. When a device becomes too hot, it may slow down or even shut down to prevent damage to the components. By using a heat sink to dissipate the excess heat, the device can operate at its optimal temperature, leading to better performance and more efficient operation.

In summary, using a heat sink can help to increase the lifespan of electronic devices by preventing premature failure due to overheating. It ensures that the device operates within its recommended temperature range, leading to longer lifespan and better performance.

Disadvantages of Using a Heat Sink

Size and Weight

When it comes to heat sinks, one of the main disadvantages is their size and weight. Heat sinks can be quite bulky and heavy, which can limit their use in applications where space is limited or weight is a concern. This can be especially problematic in portable devices or in applications where the device needs to be mounted in a specific location.

One of the reasons for the size and weight of heat sinks is that they need to be able to dissipate a large amount of heat. In order to do this effectively, they need to have a large surface area and be made of materials that are good at conducting heat. This often means that they need to be quite large and heavy in order to be effective.

In addition to the physical limitations of heat sinks, they can also be quite expensive. The cost of a heat sink can vary depending on the size and complexity of the device, as well as the materials used. This can make them less attractive as a solution in applications where cost is a concern.

Overall, the size and weight of heat sinks can be a significant disadvantage in some applications. However, they are still widely used due to their effectiveness in dissipating heat and preventing overheating in electronic devices.

Compatibility Issues

Heat sinks are designed to dissipate heat from electronic devices, but they may not be compatible with all devices. Selecting the right heat sink for a specific application can be challenging, and it may require customization or special design. This can add to the overall cost and complexity of the system.

One of the main issues with compatibility is that heat sinks are designed to fit specific sizes and shapes of electronic devices. If the heat sink is not the right size or shape, it may not fit properly, and it may not be able to dissipate heat effectively. This can lead to overheating and damage to the electronic device.

Another issue with compatibility is that some electronic devices may have specific requirements for the type of heat sink that can be used. For example, some devices may require a heat sink with a specific material or finish, or they may require a heat sink with a certain level of thermal conductivity. If the heat sink does not meet these requirements, it may not be effective in dissipating heat from the device.

Additionally, some electronic devices may have multiple heat sources that require separate heat sinks. In these cases, it may be necessary to use multiple heat sinks, which can add to the complexity and cost of the system.

Overall, compatibility issues can be a significant challenge when using heat sinks. It is important to carefully consider the specific requirements of the electronic device and select a heat sink that is designed to meet those requirements.

Limited Efficiency in Extreme Environments

Heat sinks are effective in dissipating heat from electronic devices, but they may not be as effective in extreme environments. These conditions include high altitudes and very cold temperatures. In such environments, alternative cooling methods may be required to maintain safe operating temperatures for electronic devices.

The efficiency of a heat sink is dependent on the temperature difference between the heat sink and the surrounding environment. In extreme environments, this temperature difference may be minimal, making it difficult for the heat sink to dissipate heat effectively.

In high altitudes, the air pressure is lower, which reduces the ability of the heat sink to dissipate heat. The lower air pressure means that there is less air movement over the heat sink, which reduces convection and the transfer of heat.

In very cold temperatures, the heat sink may not be able to dissipate heat effectively because the temperature difference between the heat sink and the surrounding environment is minimal. In these conditions, the heat sink may freeze, which can damage the electronic device.

Alternative cooling methods, such as liquid cooling or fans, may be required to maintain safe operating temperatures for electronic devices in extreme environments. These methods can be more complex and expensive than using a heat sink, but they may be necessary to ensure the reliable operation of electronic devices in challenging conditions.

Maintenance Requirements

One of the potential drawbacks of using a heat sink is the need for regular maintenance to ensure optimal performance. Dust and debris can accumulate on the surface of the heat sink, which can reduce its effectiveness and potentially cause damage to the electronic device. Here are some specific maintenance requirements to consider:

- Cleaning: Regular cleaning is essential to remove any dust or debris that may have accumulated on the heat sink. This can be done manually using a soft cloth or brush, or by using compressed air to blow out any loose particles.

- Inspection: It is also important to inspect the heat sink regularly for any signs of damage or wear and tear. This can include checking for any cracks or corrosion on the surface of the heat sink, as well as ensuring that all fins are intact and not bent or broken.

- Thermal Grease Reapplication: Over time, thermal grease can become dirty or worn, which can reduce its effectiveness. Therefore, it may be necessary to reapply thermal grease periodically to ensure optimal thermal conductivity between the heat sink and the electronic device.

- Replacement: If the heat sink becomes damaged or is no longer able to effectively dissipate heat, it may need to be replaced. This can be a time-consuming and costly process, depending on the size and complexity of the heat sink.

In summary, while heat sinks can be an effective solution for managing heat in electronic devices, they do require regular maintenance to ensure optimal performance. Failure to maintain the heat sink can result in reduced effectiveness and potentially damage to the electronic device.

FAQs

1. What is a heat sink?

A heat sink is a passive cooling component that is used to dissipate heat generated by electronic components. It is a metal object that absorbs heat and transfers it to the surrounding air.

2. What are the advantages of using a heat sink?

a. Improved reliability

A heat sink can help to improve the reliability of electronic components by preventing them from overheating. This can help to extend the lifespan of the components and reduce the risk of failure.

b. Increased efficiency

A heat sink can also help to increase the efficiency of electronic components by allowing them to operate at lower temperatures. This can help to improve their performance and reduce energy consumption.

c. Quieter operation

A heat sink can also help to reduce the noise levels of electronic components by reducing their temperature. This can help to make them quieter and more comfortable to use.

3. What are the disadvantages of using a heat sink?

a. Increased size and weight

A heat sink can add to the size and weight of an electronic device, which can make it less portable and more difficult to handle.

b. Increased cost

A heat sink can also add to the cost of an electronic device, which can make it less affordable for some users.

c. Limited effectiveness

A heat sink may not be effective in all situations, especially if the electronic components are producing a large amount of heat or if the heat sink is not in contact with the components. This can reduce its effectiveness and limit its usefulness.