Cooling capacity is a critical aspect of any heating, ventilation, and air conditioning (HVAC) system. It determines the amount of heat that can be removed from a room or building and is crucial in maintaining comfortable indoor temperatures. The cooling capacity of an HVAC system is influenced by several factors, including the size of the space, the number of occupants, the type of equipment used, and the climate. Understanding these factors is essential in selecting the appropriate cooling system for a particular application. In this article, we will explore the various factors that determine cooling capacity and how they interact to affect the performance of an HVAC system.

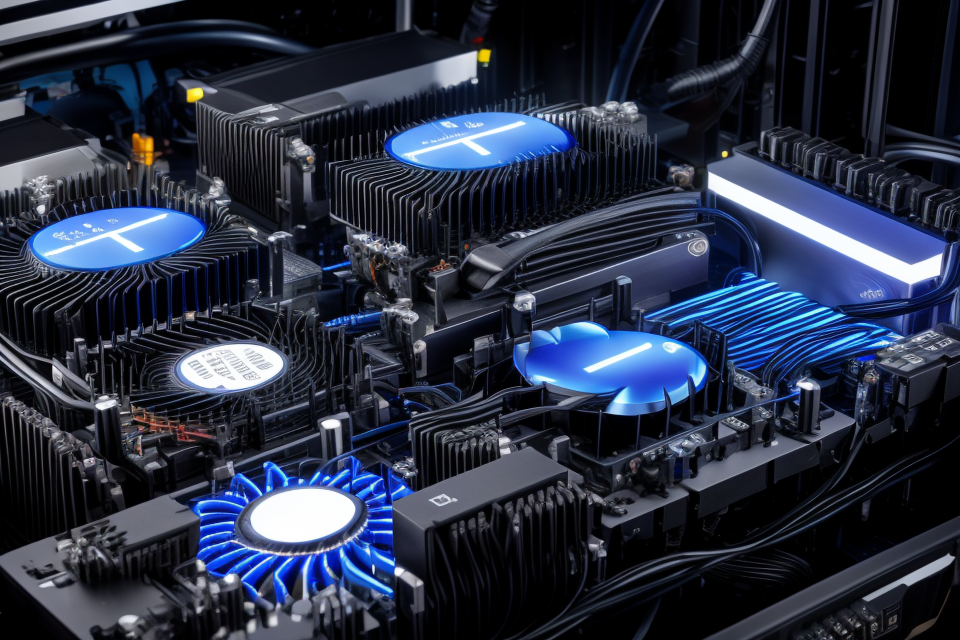

The cooling capacity of a system or device is determined by several factors, including the size and type of the heat sink, the amount and speed of the cooling medium (such as air or liquid), the design of the heat dissipation mechanism, and the thermal conductivity of the materials used. Additionally, environmental factors such as ambient temperature and humidity can also affect the cooling capacity. The goal is to ensure that the system or device stays within safe operating temperatures, while also considering factors such as cost, noise, and size.

Understanding Cooling Capacity

Definition of Cooling Capacity

Cooling capacity refers to the ability of a cooling system to remove heat from a process or environment. It is a measure of the amount of heat that can be dissipated by the cooling system, typically expressed in units of watts or horsepower. The cooling capacity of a system is determined by several factors, including the size and type of the cooling system, the materials used in the construction of the system, and the ambient temperature and humidity of the environment being cooled. Understanding the definition of cooling capacity is crucial in determining the effectiveness of a cooling system and its ability to maintain the desired temperature and humidity levels in a given environment.

Importance of Cooling Capacity

Cooling capacity is a critical factor that determines the ability of a cooling system to remove heat from a process or environment. The importance of cooling capacity can be seen in various industries, including manufacturing, data centers, and HVAC systems.

- In manufacturing, cooling capacity is essential for maintaining optimal operating temperatures of machinery and equipment, preventing overheating and potential damage.

- In data centers, cooling capacity is crucial for ensuring that servers and other IT equipment operate within safe temperature ranges, preventing overheating and potential downtime.

- In HVAC systems, cooling capacity is necessary for maintaining comfortable indoor temperatures during hot weather, improving energy efficiency and reducing the risk of equipment failure.

In summary, cooling capacity plays a vital role in maintaining the reliability, efficiency, and safety of various systems and processes. It is therefore important to understand the factors that determine cooling capacity and how to optimize it for specific applications.

Factors Affecting Cooling Capacity

- Heat Transfer Coefficients:

The heat transfer coefficient (h) is a measure of the rate at which heat is transferred between a surface and its surroundings. The higher the heat transfer coefficient, the more efficient the cooling process will be. This is because a higher heat transfer coefficient allows for more heat to be transferred from the surface being cooled to the surrounding air or liquid, resulting in a more rapid decrease in temperature. - Surface Area:

The surface area of the object being cooled is another important factor. A larger surface area means that there is more space for heat to be transferred to the surrounding air or liquid, resulting in a more efficient cooling process. Additionally, a larger surface area also allows for more heat to be transferred per unit time, which can further increase the cooling capacity. - Temperature Difference:

The temperature difference between the surface being cooled and its surroundings is also a crucial factor. The greater the temperature difference, the more heat will be transferred from the surface to its surroundings, resulting in a more efficient cooling process. This is because a larger temperature difference creates a stronger driving force for heat transfer, which drives the heat flow from the hot surface to the cooler surroundings. - Flow Rate:

The flow rate of the fluid or air over the surface being cooled is another important factor. A higher flow rate increases the amount of heat that can be transferred to the surrounding fluid or air, resulting in a more efficient cooling process. This is because a higher flow rate increases the contact between the surface being cooled and the surrounding fluid or air, which enhances the heat transfer process. - Fluid Viscosity:

The viscosity of the fluid being used for cooling is also a key factor. A lower fluid viscosity allows for better heat transfer from the surface being cooled to the surrounding fluid, resulting in a more efficient cooling process. This is because a lower fluid viscosity reduces the resistance to flow, which increases the rate at which heat can be transferred from the surface to the fluid. - Convective Heat Transfer Coefficients:

Convective heat transfer coefficients (h_c) also play a crucial role in determining the cooling capacity. Convective heat transfer is the transfer of heat through the movement of a fluid, such as air or water. The convective heat transfer coefficient (h_c) describes the rate at which heat is transferred through this movement of fluid. A higher convective heat transfer coefficient results in a more efficient cooling process, as more heat is transferred from the surface being cooled to the surrounding fluid. - Radiative Heat Transfer Coefficients:

Radiative heat transfer coefficients (h_r) also play a role in determining the cooling capacity. Radiative heat transfer is the transfer of heat through electromagnetic radiation, such as infrared radiation. The radiative heat transfer coefficient (h_r) describes the rate at which heat is transferred through this radiation. A higher radiative heat transfer coefficient results in a more efficient cooling process, as more heat is transferred from the surface being cooled to the surrounding air or liquid.

Types of Cooling Systems

Air Conditioning Systems

Air conditioning systems are a popular choice for cooling large buildings, commercial spaces, and residential homes. They work by removing heat from the interior of a space and transferring it to the exterior. There are several types of air conditioning systems, each with its own unique set of features and benefits.

Central Air Conditioning Systems

Central air conditioning systems are designed to cool an entire building or home. They consist of a single unit that is installed outside the building, usually on the roof or in a dedicated equipment room. The unit is connected to a network of ducts that distribute the cooled air throughout the building. Central air conditioning systems are typically more efficient than other types of air conditioning systems, as they can cool large spaces more effectively.

Ductless Air Conditioning Systems

Ductless air conditioning systems, also known as mini-split systems, are designed for buildings or homes that do not have ductwork. They consist of an outdoor unit that is installed outside the building, and one or more indoor units that are installed in the rooms that need to be cooled. Ductless systems are more flexible than central air conditioning systems, as they can be installed in buildings or homes of any size. They are also more energy-efficient than window air conditioners, as they do not lose cooled air through the windows.

Window Air Conditioners

Window air conditioners are designed for small spaces, such as apartments or single-room offices. They are installed in a window and use the window as a vent to exhaust the hot air from the room. Window air conditioners are the least expensive type of air conditioning system, but they are also the least efficient. They are also the least flexible, as they can only be used in rooms with windows.

Evaporative Coolers

Evaporative coolers, also known as swamp coolers, are designed for use in dry climates. They work by drawing in hot, dry air and passing it over a wet pad. The hot air is then cooled as it evaporates the water on the pad. Evaporative coolers are more energy-efficient than air conditioning systems, but they are not as effective in humid climates. They are also less expensive than air conditioning systems, but they require more maintenance.

In conclusion, the type of air conditioning system that is best for a particular building or home depends on several factors, including the size of the space, the climate, and the budget. Each type of air conditioning system has its own unique set of features and benefits, and choosing the right one can make a big difference in the comfort and efficiency of a building or home.

Refrigeration Systems

Refrigeration systems are designed to transfer heat from one location to another, typically from a warm environment to a cooler one. The main purpose of refrigeration systems is to cool and preserve food, beverages, and other perishable items. However, they also play a crucial role in cooling industrial processes and buildings.

Refrigeration systems work by using a refrigerant, which is a substance that can absorb heat at low temperatures and release it at higher temperatures. The refrigerant is compressed, which raises its temperature and pressure, then passed through a coil filled with cold water or air, which causes the refrigerant to release its heat. The refrigerant is then condensed back into a liquid, and the heat is transferred to the surrounding environment.

The cooling capacity of a refrigeration system is determined by several factors, including the size of the system, the type of refrigerant used, the efficiency of the compressor, and the insulation of the system. The larger the system, the more cooling capacity it will have. The type of refrigerant used also affects the cooling capacity, as some refrigerants are more efficient than others. The efficiency of the compressor also plays a role, as a more efficient compressor will use less energy to produce more cooling. Finally, the insulation of the system helps to minimize heat transfer to the surrounding environment, which can increase the cooling capacity.

Overall, refrigeration systems are a crucial component of many cooling applications, and understanding the factors that determine their cooling capacity is essential for optimizing their performance.

Evaporative Cooling Systems

Evaporative cooling systems rely on the principle of evaporation to cool the air. In these systems, water is evaporated into the air, which lowers the temperature of the surrounding environment. There are several types of evaporative cooling systems, including:

- Open evaporative cooling systems: In this type of system, water is sprayed into the air through nozzles or misting heads. The water droplets evaporate into the air, cooling the surrounding environment. This type of system is commonly used in hot climates to cool outdoor areas.

- Closed evaporative cooling systems: In this type of system, water is evaporated into the air through a closed-loop system. The water is pumped through a wet pad or a mesh pad, where it evaporates into the air. The evaporated water is then collected and recirculated through the system. This type of system is commonly used in commercial and industrial applications.

- Hybrid evaporative cooling systems: These systems combine the principles of both open and closed evaporative cooling systems. They use a wet pad or a mesh pad to evaporate water into the air, but they also incorporate a fan to distribute the cooled air throughout the space. This type of system is commonly used in residential and commercial applications.

The effectiveness of evaporative cooling systems depends on several factors, including the temperature and humidity of the surrounding environment, the size and design of the system, and the type of evaporative media used. Evaporative cooling systems are generally more effective in hot and dry climates, where the air is less humid. They are also more energy-efficient than other types of cooling systems, as they do not require the use of refrigerants or other chemicals. However, they can be less effective in humid climates, as the increased humidity can reduce the effectiveness of the evaporation process.

Factors Affecting Cooling Capacity

Ambient Temperature

Ambient temperature is a crucial factor that affects the cooling capacity of a system. As the ambient temperature increases, the cooling capacity of the system decreases. This is because the heat load on the system increases as the ambient temperature rises, making it more difficult for the cooling system to dissipate the heat generated by the system.

Additionally, the efficiency of the cooling system also decreases at higher ambient temperatures. This is because the temperature difference between the system and the ambient temperature becomes smaller, reducing the ability of the cooling system to transfer heat away from the system.

Moreover, high ambient temperatures can also cause the cooling system to work at higher capacities, which can lead to increased energy consumption and higher operating costs.

In summary, ambient temperature is a critical factor that affects the cooling capacity of a system. As the ambient temperature increases, the cooling capacity of the system decreases, and the efficiency of the cooling system also decreases. Additionally, high ambient temperatures can cause the cooling system to work at higher capacities, leading to increased energy consumption and higher operating costs.

Humidity

Humidity is a critical factor that affects the cooling capacity of a building or a space. The humidity level inside a building can significantly impact the performance of the cooling system. In this section, we will discuss the role of humidity in determining the cooling capacity of a building.

Impact of Humidity on Cooling Capacity

High humidity levels can make it difficult for a cooling system to maintain a comfortable indoor temperature. When the air is humid, it can feel warmer than it actually is, which can cause the cooling system to work harder to cool the space. This can result in higher energy consumption and reduced cooling capacity.

On the other hand, low humidity levels can also impact the cooling capacity of a building. When the air is too dry, it can cause the body’s natural cooling mechanism to malfunction, making it difficult to maintain a comfortable temperature. This can lead to discomfort and increased energy consumption as the cooling system works harder to maintain a comfortable temperature.

Managing Humidity for Optimal Cooling Capacity

Managing the humidity level inside a building is crucial for optimal cooling capacity. The ideal humidity level for indoor spaces is between 30% and 60%. Humidity levels above or below this range can negatively impact the cooling capacity of a building.

To maintain optimal humidity levels, it is recommended to use a humidifier or a dehumidifier as needed. A humidifier can add moisture to the air, while a dehumidifier can remove excess moisture from the air. This can help to maintain the ideal humidity level for optimal cooling capacity.

In addition, it is essential to regularly maintain the cooling system to ensure that it is functioning correctly. Regular maintenance can help to prevent issues such as clogged filters or malfunctioning fans, which can impact the cooling capacity of a building.

In conclusion, humidity is a critical factor that affects the cooling capacity of a building. Managing the humidity level inside a building is crucial for optimal cooling capacity. By maintaining the ideal humidity level and regularly maintaining the cooling system, it is possible to optimize the cooling capacity of a building and ensure a comfortable indoor temperature.

Insulation

Proper insulation plays a crucial role in determining the cooling capacity of a building. Insulation acts as a barrier that helps to maintain the temperature inside the building by reducing heat transfer through the walls, roof, and floors. The effectiveness of insulation depends on its thickness, material, and location.

One of the most common types of insulation used in buildings is thermal insulation, which is designed to reduce heat transfer through the walls, roof, and floors. Thermal insulation can be made from a variety of materials, including fiberglass, cellulose, and spray foam. The material chosen will depend on factors such as the size of the building, the climate, and the desired level of insulation.

In addition to reducing heat transfer, insulation can also help to improve indoor air quality by reducing the amount of dust and pollen that enters the building. This is because insulation helps to reduce air infiltration, which can lead to drafts and uncomfortable temperatures.

Proper insulation can also help to reduce the energy consumption of a building by reducing the need for heating and cooling. This is because insulation helps to maintain the temperature inside the building, which can lead to lower energy bills and a more comfortable indoor environment.

In conclusion, insulation is a critical factor in determining the cooling capacity of a building. Proper insulation can help to reduce heat transfer, improve indoor air quality, and reduce energy consumption, making it an essential component of any building’s design.

Heat Load

Heat load is one of the most critical factors that determine the cooling capacity of a system. It refers to the amount of heat that needs to be removed from a process or environment, and it is typically measured in watts or kilowatts. The heat load can vary depending on the specific application and can be influenced by several factors, including:

- Process temperature: The higher the process temperature, the more heat that needs to be removed, which increases the heat load.

- Process volume: The larger the volume of the process, the more heat that needs to be removed, which increases the heat load.

- Number of heat sources: The more heat sources there are, the higher the heat load.

- Heat transfer coefficients: The efficiency of the heat transfer process can also affect the heat load. A lower heat transfer coefficient can result in a higher heat load.

It is important to accurately measure the heat load in order to properly size the cooling system. An inadequate cooling system can result in overheating, which can lead to reduced productivity, equipment damage, and even safety hazards. On the other hand, an oversized cooling system can result in increased energy consumption and higher costs. Therefore, it is essential to accurately determine the heat load and select a cooling system that is appropriately sized to meet the specific needs of the application.

Air Flow

Air flow is a critical factor that determines the cooling capacity of a cooling system. The amount of air that is able to flow through the system is directly proportional to the cooling capacity. When the air flow is restricted, the cooling capacity of the system is also reduced. Therefore, it is important to ensure that the air flow is not restricted in any way.

One of the primary ways to increase the air flow is by increasing the size of the fan or using multiple fans. This will increase the amount of air that is able to flow through the system, which in turn will increase the cooling capacity.

Another way to increase the air flow is by ensuring that the vents and other openings in the system are not blocked. Any blockage in the system will restrict the air flow and reduce the cooling capacity. Therefore, it is important to keep the vents and openings clean and free from any obstructions.

It is also important to ensure that the air flow is not directed away from the critical components that need to be cooled. The direction of the air flow should be such that it is able to cool the critical components effectively. This can be achieved by positioning the fan in such a way that it directs the air flow towards the critical components.

In addition to these factors, the temperature and humidity of the air also play a crucial role in determining the cooling capacity. Therefore, it is important to ensure that the air is clean and free from any contaminants that may reduce the cooling capacity.

Maintenance

Effective maintenance is a critical factor in determining the cooling capacity of a system. Neglecting regular maintenance can result in the buildup of dirt, dust, and debris, which can reduce the efficiency of the cooling system. Here are some key aspects of maintenance that can impact cooling capacity:

- Cleaning and Debris Removal: Regular cleaning of the cooling system, including the removal of dust and debris, is essential for maintaining optimal performance. The buildup of dirt and debris can restrict airflow, increase resistance, and cause the system to work harder, resulting in reduced cooling capacity.

- Lubrication: Lubricating moving parts, such as fans and bearings, helps to reduce friction and wear, which can affect the cooling capacity. Proper lubrication ensures smooth operation and can prevent overheating, which can cause a decrease in cooling capacity.

- Inspection and Repair: Regular inspection of the cooling system can help identify any potential issues or wear and tear that may affect the cooling capacity. Addressing any problems, such as leaks, worn-out parts, or malfunctioning components, can help maintain the cooling capacity and prevent further damage.

- Temperature Monitoring: Monitoring the temperature of the cooling system can help identify any issues or inefficiencies that may impact the cooling capacity. Abnormal temperature readings may indicate a problem, such as a malfunctioning component or a blockage in the system, which can be addressed through maintenance and repair.

- Following Manufacturer Guidelines: Following the manufacturer’s guidelines for maintenance and upkeep is crucial for maintaining the cooling capacity of the system. Manufacturers provide specific instructions and recommendations for maintenance, which can help ensure optimal performance and prevent any issues that may affect the cooling capacity.

Determining Cooling Capacity

Load Calculation

Efficient cooling capacity is essential for the optimal performance of data centers, which is directly proportional to the load calculation. The load calculation determines the amount of heat that needs to be dissipated from the data center. The process of load calculation is critical for data center designers and operators as it helps in selecting the right cooling equipment and optimizing energy consumption.

There are different methods to calculate the load, but the most common one is the IT load calculation. This method considers the power consumption of IT equipment, including servers, storage devices, and network equipment. The IT load calculation involves measuring the power consumption of each device and summing it up to determine the total power consumption of the data center.

The power consumption of the IT equipment is directly proportional to the amount of heat generated. The heat generated by the IT equipment is the primary source of heat load in the data center. The heat load can be calculated by multiplying the power consumption of each device by its corresponding power density. The power density is the amount of heat generated per unit of power consumed.

Once the heat load is calculated, the next step is to determine the cooling capacity required to dissipate the heat. The cooling capacity is calculated by subtracting the heat load from the ambient temperature to determine the temperature rise. The temperature rise is the difference between the desired inlet temperature and the ambient temperature. The cooling capacity required is directly proportional to the temperature rise.

In addition to the IT load calculation, the cooling capacity calculation also considers other factors such as the room density, the number of IT devices, and the location of the data center. The room density is the ratio of the IT equipment floor area to the total floor area of the data center. The higher the room density, the more heat is generated, and the more cooling capacity is required.

The number of IT devices in the data center also affects the cooling capacity required. The more the number of devices, the more heat is generated, and the more cooling capacity is required. The location of the data center also plays a significant role in determining the cooling capacity required. Data centers located in areas with high ambient temperatures require more cooling capacity than those located in areas with lower ambient temperatures.

In conclusion, the load calculation is a critical factor in determining the cooling capacity required for data centers. The IT load calculation considers the power consumption of IT equipment, including servers, storage devices, and network equipment. The heat load is calculated by multiplying the power consumption of each device by its corresponding power density. The cooling capacity required is calculated by subtracting the heat load from the ambient temperature to determine the temperature rise. The load calculation also considers other factors such as the room density, the number of IT devices, and the location of the data center.

System Selection

Selecting the appropriate cooling system is critical in determining the cooling capacity of a facility. There are various types of cooling systems available, each with its own advantages and disadvantages. Some of the factors to consider when selecting a cooling system include:

- Climate: The climate of the location where the facility is located can significantly impact the type of cooling system that is most appropriate. For example, in hot and humid climates, evaporative cooling systems may be more effective than vapor-compression systems.

- Building Size: The size of the facility can also impact the selection of the cooling system. Larger facilities may require more powerful cooling systems to maintain the desired temperature.

- Cost: The cost of the cooling system is an important factor to consider. While some systems may be more expensive upfront, they may be more cost-effective in the long run due to lower energy consumption.

- Energy Efficiency: Energy efficiency is a critical factor to consider when selecting a cooling system. Systems with higher energy efficiency ratings can save money on energy costs over time.

- Maintenance: The maintenance requirements of the cooling system should also be considered. Some systems may require more frequent maintenance than others, which can impact the overall cost of ownership.

By carefully considering these factors, facility managers can select the appropriate cooling system to meet their needs and ensure optimal cooling capacity.

Sizing Equipment

Proper sizing of equipment is crucial in determining the cooling capacity of a system. It involves selecting the appropriate size of the cooling equipment based on the expected cooling load. Here are some factors to consider when sizing equipment:

- Cooling Load: The cooling load is the amount of heat that needs to be removed from the system. It is calculated based on the amount of heat generated by the equipment, the ambient temperature, and the number of hours of operation.

- Flow Rate: The flow rate of the cooling fluid is also an important factor to consider. It determines the amount of heat that can be transferred from the system to the cooling fluid.

- Temperature Difference: The temperature difference between the system and the cooling fluid is also a critical factor. A higher temperature difference will result in a higher cooling capacity.

- Pressure Drop: The pressure drop across the cooling equipment is also an important consideration. A higher pressure drop will reduce the flow rate and the cooling capacity of the system.

- Maintenance: The size of the cooling equipment should also take into account the maintenance requirements. A larger cooling equipment may require more maintenance, which can affect its availability and performance.

In summary, sizing equipment is a critical factor in determining the cooling capacity of a system. It involves selecting the appropriate size of the cooling equipment based on the expected cooling load, flow rate, temperature difference, pressure drop, and maintenance requirements. Proper sizing of equipment can help ensure efficient and effective cooling, reduce energy consumption, and improve the overall performance of the system.

Monitoring and Adjustment

Monitoring and adjustment play a crucial role in determining the cooling capacity of a system. By regularly monitoring the temperature and flow rate of the coolant, technicians can quickly identify any issues that may affect the cooling capacity of the system. This information can then be used to make adjustments to the system to ensure that it is operating at maximum efficiency.

There are several key factors that need to be monitored when determining cooling capacity. These include:

- Temperature: The temperature of the coolant should be closely monitored to ensure that it is within the appropriate range for the system. If the temperature is too high, it may indicate a problem with the cooling system, such as a clogged radiator or a malfunctioning fan.

- Flow rate: The flow rate of the coolant should also be monitored to ensure that it is within the appropriate range. If the flow rate is too low, it may indicate a blockage in the cooling system, such as a clogged hose or a malfunctioning pump.

- Pressure: The pressure of the coolant should also be monitored to ensure that it is within the appropriate range. If the pressure is too high, it may indicate a problem with the cooling system, such as a malfunctioning pressure relief valve.

By regularly monitoring these factors, technicians can quickly identify any issues that may affect the cooling capacity of the system. This information can then be used to make adjustments to the system to ensure that it is operating at maximum efficiency. For example, if the temperature of the coolant is too high, technicians may adjust the fan speed or clean the radiator to improve the cooling capacity of the system. Similarly, if the flow rate is too low, technicians may adjust the pump speed or replace a clogged hose to improve the cooling capacity of the system.

Overall, monitoring and adjustment are critical components of determining the cooling capacity of a system. By regularly monitoring the temperature, flow rate, and pressure of the coolant, technicians can quickly identify any issues that may affect the cooling capacity of the system and make adjustments to ensure that it is operating at maximum efficiency.

Key Takeaways

- Cooling capacity is influenced by various factors, including the size and layout of the building, the number and placement of windows, the insulation of the building envelope, and the type and efficiency of cooling equipment.

- Proper design and installation of cooling equipment can significantly impact the efficiency and effectiveness of the cooling system.

- Building occupants’ behavior, such as the use of natural ventilation and the adjustment of thermostat settings, can also affect the cooling capacity of a building.

- Regular maintenance and monitoring of the cooling system can help ensure optimal performance and prevent breakdowns, which can affect the cooling capacity of the building.

Future Research Directions

Investigating Novel Materials for Enhanced Cooling Capacity

One promising avenue for future research is the exploration of novel materials with improved thermal conductivity and heat transfer properties. These materials could be integrated into advanced cooling systems to enhance their cooling capacity and efficiency. By investigating their properties and potential applications, researchers may identify new materials that could revolutionize the design of cooling systems.

Integration of Nanotechnology in Cooling Systems

Another potential area for future research is the integration of nanotechnology in cooling systems. The use of nanomaterials and nanostructures could enable more efficient heat transfer and improve the overall performance of cooling systems. This includes the development of nanofluids, which have unique thermal properties due to their small size and high surface area, and the integration of nanoscale heat exchangers in cooling systems.

Optimization of Cooling System Design and Configuration

Future research could also focus on optimizing the design and configuration of cooling systems to maximize their cooling capacity. This may involve developing new models and simulation tools to predict the performance of different cooling system configurations under various operating conditions. By analyzing the results of these simulations, researchers can identify the most effective designs and configurations for specific applications, leading to more efficient and reliable cooling systems.

Investigating the Impact of Environmental Factors on Cooling Capacity

Finally, future research could explore the impact of environmental factors on cooling capacity. This includes investigating the effects of temperature, humidity, and air flow on the performance of cooling systems. By understanding how these factors influence the heat transfer process, researchers can develop more accurate models and improve the performance of cooling systems in various environments.

Overall, future research in the area of cooling capacity has the potential to drive significant advancements in the design and performance of cooling systems. By exploring novel materials, integrating nanotechnology, optimizing system design, and investigating environmental factors, researchers can contribute to the development of more efficient and reliable cooling systems that meet the growing demands of various industries.

FAQs

1. What is cooling capacity?

Cooling capacity refers to the ability of a cooling system to remove heat from a given space or environment. It is typically measured in terms of the amount of heat that can be removed per unit of time, and is often expressed in units of watts or BTUs.

2. What factors determine cooling capacity?

There are several factors that can affect the cooling capacity of a system, including the size and design of the cooling equipment, the type and amount of refrigerant used, the ambient temperature and humidity, and the amount of heat that needs to be removed. Other factors, such as the efficiency of the system and the presence of any obstructions or impediments to airflow, can also impact the cooling capacity of a system.

3. How is cooling capacity calculated?

There are several methods for calculating cooling capacity, depending on the specific system and application. In general, however, cooling capacity is calculated by determining the amount of heat that needs to be removed, and then selecting a cooling system that is capable of removing that amount of heat within the desired timeframe. This may involve considering factors such as the size and type of the cooling equipment, the efficiency of the system, and the ambient temperature and humidity.

4. How can I improve the cooling capacity of my system?

There are several ways to improve the cooling capacity of a system, including increasing the size or efficiency of the cooling equipment, using higher-quality refrigerants, improving the airflow through the system, and reducing the amount of heat that needs to be removed. Other strategies, such as using energy-efficient lighting or insulation, can also help to improve the overall efficiency of the system and increase its cooling capacity.