A heat sink environment is a system that is designed to dissipate heat from electronic components. It is a crucial component in the design of many devices, from computers to smartphones, that generates a significant amount of heat during operation. In this article, we will explore what a heat sink environment is, how it works, and its importance in the world of electronics.

Body:

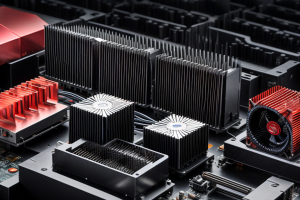

A heat sink environment is a passive or active system that transfers heat away from electronic components to prevent overheating. The heat sink environment typically consists of a metal plate or fins that increase the surface area for heat dissipation. This design helps to draw heat away from the component and into the surrounding air.

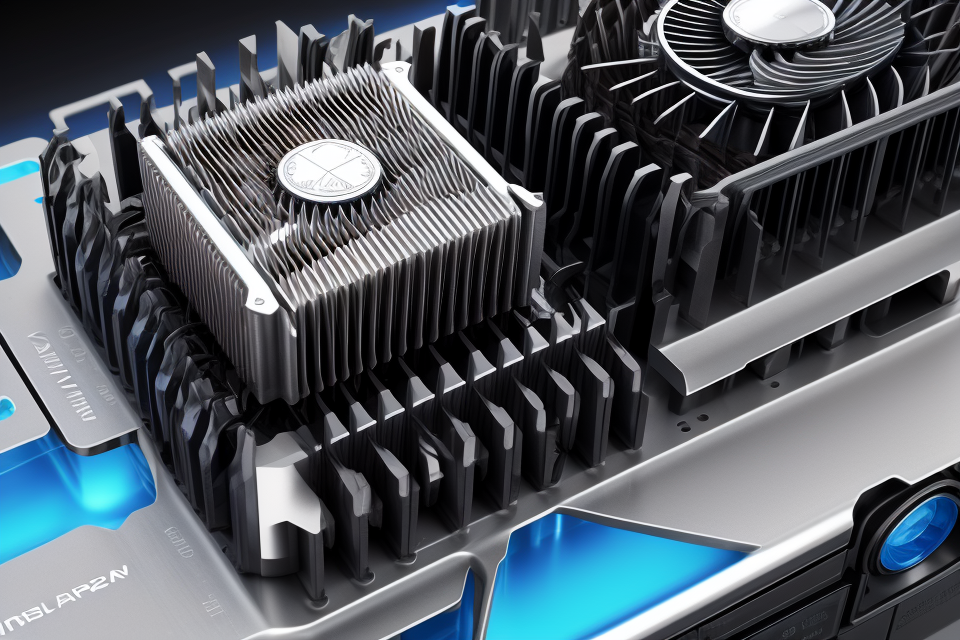

Passive heat sinks rely on natural convection to dissipate heat, while active heat sinks use fans or other mechanisms to force air over the heat sink. Active heat sinks are more effective but also more complex and require power to operate.

The heat sink environment is essential in preventing electronic components from overheating, which can cause damage or reduce the lifespan of the device. In some cases, overheating can even lead to a catastrophic failure, such as a fire.

Conclusion:

In conclusion, a heat sink environment is a critical component in the design of many electronic devices. It plays a vital role in preventing overheating and ensuring the reliable operation of electronic components. Understanding how a heat sink environment works can help you choose the right heat sink for your next project and ensure that your devices run smoothly and safely.

A heat sink environment is a type of cooling system used to dissipate heat generated by electronic components and devices. It works by transferring heat from the components to a heat sink, which is typically a metal plate or fin structure that has a large surface area and is in contact with a cooling fluid, such as air or liquid. The heat sink transfers the heat to the cooling fluid, which then carries it away from the components and dissipates it into the surrounding environment. The heat sink environment is commonly used in computer systems, power electronics, and other applications where heat generation is a concern.

Understanding Heat Sink Environments

Definition of a Heat Sink Environment

A heat sink environment is a passive or active system designed to dissipate excess heat generated by electronic components, devices, or machines. The primary purpose of a heat sink environment is to maintain optimal operating temperatures for the components, extend their lifespan, and prevent overheating-related malfunctions or failures.

Key components of a heat sink environment:

- Heat-generating components: These are the electronic components or devices that produce heat during operation, such as processors, power supplies, and motor windings.

- Heat sink: A heat sink is a component that transfers heat from the heat-generating components to the surrounding environment. It may be a passive component, such as a fin or a base plate, or an active component, such as a fan or a pump.

- Thermal interface materials (TIMs): TIMs are materials placed between the heat-generating components and the heat sink to enhance heat transfer. Examples of TIMs include thermal paste, thermal pads, and thermal tapes.

- Cooling fans or pumps: These are active components that help move heat-transfer fluids, such as air or liquid, between the heat sink and the surrounding environment.

- Ducts or channels: These are passive or active components that direct the flow of heat-transfer fluids to and from the heat sink. Ducts or channels may be integrated into the design of the heat sink environment or installed separately.

- Environmental controls: Environmental controls, such as temperature sensors, thermostats, and humidity controls, help manage the ambient environment in which the heat sink environment operates. These controls ensure that the heat sink environment operates within the optimal temperature and humidity range for efficient heat dissipation.

Importance of Heat Sink Environments

Heat sink environments play a crucial role in protecting electronic devices from overheating and damage. When electronic devices operate, they generate heat which can cause damage to the device if not properly managed. Heat sink environments are designed to dissipate heat away from the device, preventing it from overheating and ensuring optimal performance.

In addition to protecting electronic devices, heat sink environments also play a critical role in ensuring that devices operate at their maximum potential. Electronic devices are designed to operate within a specific temperature range, and if they become too hot, their performance can be negatively affected. Heat sink environments help to maintain the device’s temperature within the safe operating range, ensuring that it operates at its maximum potential.

Overall, the importance of heat sink environments cannot be overstated. They play a critical role in protecting electronic devices from damage and ensuring that they operate at their maximum potential.

Types of Heat Sink Environments

There are three main types of heat sink environments: active, passive, and hybrid.

Active Heat Sink Environments

Active heat sink environments involve the use of fans or other mechanical devices to actively circulate air or liquid around the heat-generating components. This helps to remove heat from the environment and maintain a safe temperature. Active heat sinks are commonly used in electronic devices such as computers, servers, and data centers.

Passive Heat Sink Environments

Passive heat sink environments rely on natural convection and radiation to dissipate heat. These environments do not have any moving parts, making them more reliable and low-maintenance. Passive heat sinks are commonly used in environments where there is a low risk of overheating, such as in industrial applications.

Hybrid Heat Sink Environments

Hybrid heat sink environments combine the principles of active and passive heat sinks. These environments use active cooling methods in conjunction with passive cooling methods to provide efficient heat dissipation. Hybrid heat sinks are commonly used in high-performance computing and gaming applications.

Overall, the type of heat sink environment used depends on the specific requirements of the application and the amount of heat that needs to be dissipated. Each type of heat sink environment has its own advantages and disadvantages, and the appropriate type must be chosen based on the specific needs of the system.

How Heat Sink Environments Work

The Science Behind Heat Sink Environments

In order to understand the science behind heat sink environments, it is important to first understand the concept of thermal management. Thermal management refers to the process of controlling the temperature of a system or device to ensure that it operates within safe and efficient parameters.

Heat transfer mechanisms play a crucial role in thermal management. There are three primary heat transfer mechanisms: conduction, convection, and radiation.

Conduction is the transfer of heat through direct contact between two objects. This occurs when heat flows from a hotter to a cooler object.

Convection is the transfer of heat through the movement of a fluid, such as air or water. This occurs when heat flows from a hotter to a cooler area.

Radiation is the transfer of heat through electromagnetic waves. This occurs when heat flows from a hotter to a cooler object, regardless of the presence of a medium.

Cooling technologies are used to remove heat from a system or device. There are several types of cooling technologies, including air cooling, liquid cooling, and phase change cooling.

Air cooling is the most common type of cooling technology. It involves using air to remove heat from a system or device. This can be achieved through natural convection, where air is allowed to flow over the surface of the object, or forced convection, where air is blown over the surface of the object.

Liquid cooling involves using a liquid, such as water or a specialized coolant, to remove heat from a system or device. This can be achieved through direct contact between the liquid and the object, or by using a heat exchanger.

Phase change cooling involves using a substance that changes phase, such as ice or a liquid-vapor mixture, to remove heat from a system or device. This can be achieved through direct contact between the substance and the object, or by using a heat exchanger.

In conclusion, the science behind heat sink environments involves understanding the mechanisms of heat transfer and the various cooling technologies used to remove heat from a system or device.

Design Considerations for Heat Sink Environments

When designing a heat sink environment, there are several key considerations that must be taken into account to ensure its effectiveness. These considerations include material selection, geometric design, and airflow optimization.

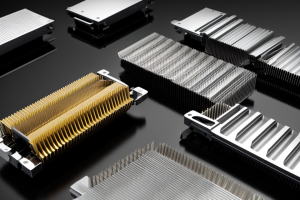

Material Selection

The material selection for a heat sink environment is critical as it will determine the thermal conductivity and durability of the heat sink. Common materials used for heat sinks include aluminum, copper, and alloys such as copper-beryllium and aluminum-silicon. The thermal conductivity of these materials varies, and the selection of the most appropriate material depends on the specific application requirements.

For example, aluminum is a popular choice for heat sinks due to its low cost and high thermal conductivity. However, copper has a higher thermal conductivity than aluminum and is often used in high-performance applications. Copper-beryllium and aluminum-silicon alloys are also used in specialized applications due to their high thermal conductivity and corrosion resistance.

Geometric Design

The geometric design of a heat sink is also an important consideration. The shape and size of the heat sink will affect the rate at which it can dissipate heat. A well-designed heat sink can increase the surface area available for heat transfer, which can improve its performance.

The shape of the heat sink can also affect the flow of air around it, which can impact its cooling ability. For example, a flat plate heat sink may be more effective at dissipating heat than a fin-based heat sink, as it presents a larger surface area to the air. However, a fin-based heat sink may be more effective at dissipating heat in applications where airflow is restricted.

Airflow Optimization

Airflow optimization is also a critical consideration in the design of a heat sink environment. The flow of air around the heat sink can have a significant impact on its ability to dissipate heat. To optimize airflow, designers may use various techniques such as increasing the number of fins or using fans to force airflow over the heat sink.

The placement of the heat sink is also important, as it should be located in an area where airflow is sufficient to cool it effectively. In some cases, designers may use ducts or other airflow management systems to direct airflow over the heat sink.

Overall, the design of a heat sink environment requires careful consideration of material selection, geometric design, and airflow optimization to ensure its effectiveness in dissipating heat.

Best Practices for Implementing Heat Sink Environments

Proper installation of heat sink environments is crucial to ensure efficient heat dissipation. Before installing a heat sink, it is important to determine the appropriate size and type of heat sink for the specific application. The heat sink should be placed in close contact with the component to be cooled, and proper thermal grease should be applied between the two surfaces. It is also important to ensure that the heat sink is securely fastened to the component to prevent movement and minimize thermal resistance.

Maintenance and cleaning of heat sink environments are essential to maintain optimal performance. Dust and debris can accumulate on the surfaces of the heat sink and the component, reducing heat transfer efficiency. Regular cleaning with a soft brush or compressed air can help to remove any buildup and maintain proper airflow. Additionally, it is important to check for any damage to the heat sink or component and replace them if necessary.

Monitoring and reporting of temperature and performance data can help to optimize the performance of heat sink environments. Temperature sensors can be placed on the component and the heat sink to monitor the temperature differential between the two surfaces. This data can be used to adjust the performance of the heat sink and optimize cooling efficiency. Additionally, reporting of temperature and performance data can help to identify any potential issues and prevent downtime.

In summary, best practices for implementing heat sink environments include proper installation, maintenance and cleaning, and monitoring and reporting of temperature and performance data. Following these best practices can help to ensure efficient heat dissipation and optimal performance of the component being cooled.

Real-World Applications of Heat Sink Environments

- Data Centers

Data centers are large-scale facilities that house computer systems and associated infrastructure, such as servers, storage devices, and networking equipment. These systems generate a significant amount of heat, which can have a negative impact on performance and reliability if not properly managed. Heat sink environments in data centers help to dissipate heat and maintain optimal operating temperatures, ensuring that equipment runs efficiently and minimizing the risk of downtime or failure. - Server Rooms

Server rooms are smaller-scale environments that house server equipment, typically used by businesses or organizations to support their IT operations. Like data centers, server rooms generate heat that must be managed effectively to prevent overheating and equipment failure. Heat sink environments in server rooms help to dissipate heat and maintain safe operating temperatures, ensuring that servers run efficiently and can support the necessary workloads. - Industrial Settings

Heat sink environments are also used in industrial settings, such as manufacturing plants or processing facilities, where equipment and machinery generate significant amounts of heat. In these environments, heat sink systems help to manage heat generated by machinery and equipment, preventing overheating and minimizing the risk of equipment failure or damage. Heat sink environments in industrial settings can also help to improve energy efficiency by reducing the need for additional cooling systems or air conditioning.

Advantages and Disadvantages of Heat Sink Environments

Advantages

Extended Lifespan of Electronic Devices

Incorporating heat sink environments in electronic devices can significantly increase their lifespan. The heat sink environment helps to maintain the optimal temperature of the device’s critical components, such as processors and circuits. By doing so, it reduces the risk of overheating, which can cause damage to the components and result in a shorter lifespan for the device. Consequently, incorporating a heat sink environment can lead to a longer functional life for electronic devices, ultimately enhancing their overall performance and reliability.

Increased Reliability and Uptime

A heat sink environment plays a crucial role in ensuring that electronic devices operate at optimal levels of performance. The environment helps to regulate the temperature of the device’s critical components, preventing them from overheating. This, in turn, leads to increased reliability and uptime, as the device is less likely to experience downtime due to overheating or component failure. By incorporating a heat sink environment, electronic devices can be designed to operate more efficiently and effectively, resulting in improved overall performance and user satisfaction.

Reduced Risk of Failure

Incorporating a heat sink environment in electronic devices can significantly reduce the risk of failure. Overheating is a common cause of failure in electronic devices, as it can cause damage to critical components such as processors and circuits. By using a heat sink environment, the device’s temperature is regulated, preventing it from overheating. This reduction in the risk of failure leads to improved overall reliability and longevity for the device, enhancing its performance and ensuring that it meets the needs of users. Consequently, incorporating a heat sink environment can result in a more robust and reliable electronic device, capable of withstanding the demands of various applications.

Disadvantages

- Cost of implementation: The cost of implementing a heat sink environment can be quite high, as it requires specialized equipment and infrastructure. This may include expensive cooling systems, insulation, and other materials that can increase the upfront costs of the project.

- Energy consumption: Heat sink environments require a significant amount of energy to maintain the necessary cooling and ventilation systems. This can lead to increased energy consumption and higher utility bills, which can be a concern for businesses and organizations that are looking to reduce their carbon footprint and lower their operating costs.

- Environmental impact: The use of heat sink environments can have a negative impact on the environment, particularly if the cooling and ventilation systems rely on non-renewable energy sources. This can contribute to greenhouse gas emissions and other forms of pollution, which can have a negative impact on air quality and the environment.

It is important to carefully consider these potential disadvantages when deciding whether to implement a heat sink environment. While there are many benefits to using this technology, it is important to weigh these against the potential costs and environmental impacts.

FAQs

1. What is a heat sink environment?

A heat sink environment is a structure or mechanism designed to dissipate heat generated by electronic components or devices. It is used to prevent overheating and ensure the safe and efficient operation of the equipment.

2. How does a heat sink environment work?

A heat sink environment works by transferring heat generated by electronic components to a fluid, which then carries the heat away from the components to a location where it can be dissipated, such as the atmosphere or a cooling tower. The fluid is typically a liquid or gas, and the heat sink environment may include fans or other mechanisms to circulate the fluid and enhance heat transfer.

3. What are the benefits of using a heat sink environment?

The benefits of using a heat sink environment include improved reliability and longevity of electronic equipment, reduced risk of failure or damage due to overheating, and increased energy efficiency. In addition, a heat sink environment can help to reduce noise levels and improve the overall environmental performance of the equipment.

4. What types of heat sink environments are there?

There are several types of heat sink environments, including air-cooled heat sinks, liquid-cooled heat sinks, and two-phase heat sinks. The choice of heat sink environment depends on the specific requirements of the equipment, including the amount of heat generated, the desired temperature range, and the available space for the heat sink.

5. How is a heat sink environment designed and installed?

A heat sink environment is typically designed by engineers and installed by specialized contractors. The design of the heat sink environment takes into account factors such as the size and type of electronic components, the amount of heat generated, and the desired temperature range. The installation of the heat sink environment involves the installation of the heat sink itself, as well as any associated piping or ductwork, and the connection to the electronic components.

6. How do I maintain a heat sink environment?

Maintaining a heat sink environment involves regular inspection and cleaning of the heat sink and associated components, as well as monitoring of the fluid levels and temperatures. In addition, regular maintenance of the electronic components themselves is important to ensure optimal performance and to reduce the risk of failure or damage due to overheating.

7. Can a heat sink environment be used in all types of equipment?

A heat sink environment can be used in a wide range of equipment, including computers, servers, power supplies, and other electronic devices. However, the specific requirements of the equipment will determine the type of heat sink environment that is most appropriate, and some equipment may not be suitable for use with a heat sink environment at all.

8. How do I know if my equipment needs a heat sink environment?

If your equipment generates a significant amount of heat, or if it is operating in a high-temperature environment, it may benefit from the use of a heat sink environment. However, the specific requirements of the equipment will determine whether a heat sink environment is appropriate, and you should consult with an engineer or specialist to determine the best solution for your needs.