Electronic devices are the backbone of modern technology, enabling us to communicate, work, and play in ways that were once unimaginable. However, as these devices become more powerful, they also generate more heat, which can damage the device and reduce its lifespan. That’s where heat sinks come in. A heat sink is a passive device that helps dissipate heat from electronic components, preventing overheating and improving the overall performance of the device. But with so many different types of heat sinks on the market, how do you know which one is right for your device? In this article, we’ll explore the best heat sinks for different types of electronic devices, so you can keep your devices running cool and efficient.

The best heat sink for electronic devices depends on various factors such as the device’s power rating, size, and the type of cooling required. However, some of the most popular heat sinks include aluminum and copper-based heat sinks, which are effective in dissipating heat from electronic devices. Additionally, thermal paste or grease can be used to improve heat transfer between the heat sink and the device. It is important to choose a heat sink that is compatible with the device and meets its cooling requirements to ensure optimal performance and longevity.

Understanding Heat Sinks and Their Importance

Definition of Heat Sinks

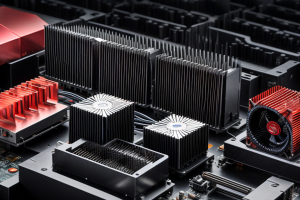

A heat sink is a passive heat exchanger that is designed to dissipate heat generated by an electronic device. It is a crucial component that helps maintain the optimal temperature of electronic devices and prevents overheating, which can cause damage to the device and reduce its lifespan. Heat sinks are typically made of metal, such as aluminum or copper, and have a large surface area to facilitate heat transfer. They are often designed with fins or channels to increase the surface area and improve heat dissipation. Heat sinks can be used in a wide range of electronic devices, including computers, servers, power supplies, and LED lights.

Types of Heat Sinks

There are several types of heat sinks that are commonly used in electronic devices. Each type has its own unique characteristics and advantages, making it suitable for different applications. The following are some of the most common types of heat sinks:

- Air-cooled heat sinks: These heat sinks rely on the air to dissipate heat from the electronic device. They are often used in small devices or applications where there is limited space for heat dissipation. Air-cooled heat sinks can be effective, but they may not be suitable for high-power devices or environments with low airflow.

- Liquid-cooled heat sinks: These heat sinks use a liquid coolant to transfer heat away from the electronic device. They are often used in high-power devices or applications where there is a need for precise temperature control. Liquid-cooled heat sinks can be more effective than air-cooled heat sinks, but they can also be more complex and expensive to implement.

- Phase-change heat sinks: These heat sinks use a phase change material (PCM) to absorb and store heat from the electronic device. The PCM then melts or freezes, transferring the heat to the surrounding environment. Phase-change heat sinks can be effective in applications where there is a need for precise temperature control, but they may not be suitable for high-power devices.

- Vapor-phase heat sinks: These heat sinks use a vapor to transfer heat away from the electronic device. They are often used in applications where there is a need for high heat transfer rates, such as in high-power devices or industrial applications. Vapor-phase heat sinks can be effective, but they can also be complex and expensive to implement.

In summary, the type of heat sink used in an electronic device will depend on the specific requirements of the application. Factors such as the power of the device, the environment in which it will be used, and the need for precise temperature control will all play a role in determining the best type of heat sink to use.

Importance of Heat Sinks in Electronic Devices

In modern technology, heat is one of the most significant factors that affect the performance and longevity of electronic devices. As devices become smaller and more powerful, they generate more heat, which can lead to malfunctioning or even damage to the device. This is where heat sinks come into play. A heat sink is a component that helps dissipate heat from electronic devices, ensuring they run smoothly and safely.

In electronic devices, heat sinks are crucial because they help maintain the temperature of the device within safe limits. Overheating can cause irreversible damage to electronic components, leading to a decrease in performance or even complete failure. By using a heat sink, the temperature of the device can be kept under control, preventing such damage from occurring.

Heat sinks also play a significant role in ensuring the reliability and longevity of electronic devices. By removing excess heat, heat sinks help to reduce the wear and tear on electronic components. This can help extend the lifespan of the device, reducing the need for frequent repairs or replacements.

Furthermore, heat sinks can improve the overall performance of electronic devices. As the temperature of the device increases, so does the speed at which the device operates. By removing excess heat, heat sinks can help to maintain a stable operating temperature, which can help to improve the performance of the device.

In summary, heat sinks are essential components in electronic devices as they help to maintain safe temperatures, prevent damage to electronic components, extend the lifespan of the device, and improve overall performance. When choosing a heat sink for your electronic device, it is important to consider factors such as size, material, and design to ensure that it is suitable for your specific needs.

Factors to Consider When Choosing a Heat Sink

Thermal Resistance

When choosing a heat sink for your electronic devices, thermal resistance is an important factor to consider. Thermal resistance refers to the ability of a material to resist the flow of heat. The lower the thermal resistance of a material, the better it is at conducting heat away from the electronic device.

There are several factors that can affect the thermal resistance of a heat sink, including the material it is made of, its shape and size, and the type of fins or protrusions it has. Some common materials used for heat sinks include aluminum, copper, and steel, each with their own thermal resistance properties.

It is important to choose a heat sink with a low thermal resistance in order to ensure that it can effectively dissipate heat from your electronic device. This is particularly important in situations where the device is operating at high temperatures or is subject to thermal stress.

When selecting a heat sink, it is important to consider the specific requirements of your electronic device. This may include factors such as the maximum operating temperature, the amount of heat that needs to be dissipated, and the available space for the heat sink. By taking these factors into account, you can choose a heat sink that is well-suited to the needs of your device and can help to prevent overheating and other thermal-related issues.

Surface Area

When choosing a heat sink for your electronic devices, one of the most important factors to consider is the surface area. The surface area of a heat sink determines how much of the device’s heat can be dissipated. A larger surface area means that more heat can be transferred to the environment, keeping the device cooler.

However, the surface area of a heat sink is not the only factor to consider. Other factors, such as the shape and material of the heat sink, also play a role in determining its effectiveness. In addition, the surface area of the heat sink must be proportional to the surface area of the device being cooled, as a larger heat sink may not always be more effective.

It is also important to note that increasing the surface area of a heat sink can also increase its weight and size, which may not be practical for all applications. Therefore, it is important to carefully consider the trade-offs when choosing a heat sink for your electronic devices.

Material

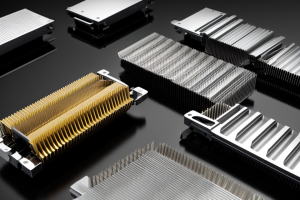

When selecting a heat sink for your electronic devices, the material is an essential factor to consider. Different materials have unique properties that can affect the performance and durability of the heat sink. Here are some common materials used in heat sinks and their characteristics:

- Aluminum: Aluminum is a popular choice for heat sinks due to its low cost and good thermal conductivity. It is also lightweight and easy to machine, making it suitable for various applications. However, aluminum is not as thermally conductive as copper, and its thermal resistance can increase with temperature.

- Copper: Copper has excellent thermal conductivity, making it an ideal material for heat sinks. It can effectively dissipate heat from electronic devices and is suitable for high-power applications. Copper is also a good conductor of electricity, which can help reduce resistance and improve the performance of the device. However, copper is more expensive than aluminum and can be more challenging to machine.

- Silicon: Silicon is a semiconductor material that can be used to make heat sinks with integrated thermal solutions. It has good thermal conductivity and can be used to dissipate heat from electronic devices. Silicon heat sinks can be made into various shapes and sizes, making them suitable for different applications. However, silicon is more expensive than aluminum or copper and may not be suitable for high-power applications.

- Graphite: Graphite is a carbon-based material that has excellent thermal conductivity. It can be used to make heat sinks for high-temperature applications, such as engines and turbines. Graphite heat sinks are lightweight and have a low thermal resistance, making them suitable for high-power applications. However, graphite is not as durable as other materials and can wear down over time.

- Conductive Plastics: Conductive plastics are a type of polymer that has been infused with conductive particles. They can be used to make heat sinks that are lightweight and flexible. Conductive plastics have good thermal conductivity and can be used for various applications. However, they may not be as effective as metal heat sinks for high-power applications.

In conclusion, the material of the heat sink can significantly impact its performance and durability. Factors such as cost, thermal conductivity, and suitability for the application should be considered when selecting a heat sink material.

Compatibility with Electronic Devices

When selecting a heat sink for your electronic devices, compatibility is a crucial factor to consider. A heat sink must fit the device it is designed to cool, both physically and electrically. The size, shape, and mounting method of the heat sink must match the device’s requirements. In addition, the heat sink must be compatible with the device’s operating voltage and current ratings.

It is important to note that some heat sinks are designed for specific devices or applications, so it is essential to ensure that the heat sink you choose is compatible with your device. If you are unsure about compatibility, it is advisable to consult the manufacturer’s specifications or seek the advice of a qualified technician.

Another factor to consider is the thermal performance of the heat sink. The heat sink must be capable of dissipating the heat generated by the device effectively. The thermal performance of a heat sink is typically measured in terms of its thermal resistance (R-value) or its capacity to dissipate heat per unit area (thermal dissipation). It is important to choose a heat sink with a low R-value or high thermal dissipation capacity to ensure efficient heat transfer and prevent overheating of the device.

In summary, compatibility is a critical factor to consider when choosing a heat sink for your electronic devices. It is important to ensure that the heat sink fits the device physically and electrically, is compatible with its operating voltage and current ratings, and has the necessary thermal performance to effectively dissipate the heat generated by the device.

Popular Heat Sink Solutions and Their Pros and Cons

1. Air-based Heat Sinks

Air-based heat sinks are the most common type of heat sink used in electronic devices. They work by allowing air to flow over the surface of the heat sink, which helps to dissipate heat. The design of air-based heat sinks can vary widely, from simple fin designs to more complex turbulator designs.

Pros:

- Inexpensive

- Widely available

- Can be very effective in dissipating heat

Cons:

- May not be as effective in high-temperature environments

- May require a fan to be effective

- Can be bulky and take up space in electronic devices

Despite their limitations, air-based heat sinks are still a popular choice for many electronic devices due to their low cost and wide availability. They are also relatively easy to install and can be very effective in dissipating heat, especially when combined with a fan. However, they may not be the best choice for high-temperature environments or for devices where space is at a premium.

2. Liquid-based Heat Sinks

Liquid-based heat sinks, also known as phase change cooling, utilize a liquid coolant to transfer heat away from electronic components. They are particularly effective in high-performance computing applications, such as servers and data centers. Here’s a closer look at the pros and cons of liquid-based heat sinks:

Pros:

- High heat transfer efficiency: Liquid-based heat sinks have a high heat transfer coefficient due to the large surface area of the liquid in contact with the heat source. This makes them more effective at dissipating heat than air or solid-based heat sinks.

- Flexibility in design: Liquid-based heat sinks can be designed to fit a wide range of component layouts and sizes, making them versatile for use in various electronic devices.

- Quiet operation: Unlike air-based cooling systems, liquid-based heat sinks operate silently, making them ideal for noise-sensitive environments such as data centers or offices.

- Reduced maintenance: Since there are no moving parts, liquid-based heat sinks require minimal maintenance and have a longer lifespan compared to fans or blowers in air-based cooling systems.

Cons:

- Complexity and cost: Liquid-based heat sinks are generally more complex and expensive to implement compared to air or solid-based heat sinks due to the requirement for a separate liquid cooling system, including pumps, tubing, and radiators.

- Risk of leaks: Since the liquid coolant is in contact with electronic components, there is a risk of liquid leaks which could potentially cause damage to the devices. This requires careful design and maintenance to prevent leaks and ensure proper cooling.

- Maintenance of the cooling system: The liquid cooling system, including the pumps, tubing, and radiators, needs regular maintenance to ensure optimal performance and prevent blockages or leaks. This adds to the overall complexity and cost of the heat sink solution.

- Limited scalability: While liquid-based heat sinks can be designed for a wide range of applications, they may not be the most practical solution for small or portable devices due to the additional weight and space requirements of the liquid cooling system.

In summary, liquid-based heat sinks offer high heat transfer efficiency and flexibility in design, making them a popular choice for high-performance computing applications. However, their complexity, cost, and potential for leaks should be considered when evaluating their suitability for different electronic devices.

3. Phase Change Heat Sinks

Phase change heat sinks are a type of heat sink that utilizes a phase change material (PCM) to absorb and dissipate heat from electronic devices. PCMs are materials that undergo a change in phase at a specific temperature, such as melting or freezing. When a PCM absorbs heat, it undergoes a phase change, which allows it to store a large amount of thermal energy.

One of the main advantages of phase change heat sinks is their ability to store a large amount of thermal energy. This means that they can effectively dissipate heat from electronic devices over a longer period of time than other types of heat sinks. Additionally, phase change heat sinks are often more compact and lightweight than other types of heat sinks, making them ideal for use in portable electronic devices.

However, phase change heat sinks also have some disadvantages. One of the main drawbacks is that they can be more expensive than other types of heat sinks. Additionally, phase change heat sinks may not be as effective at dissipating heat in certain situations, such as when the electronic device is operating at high temperatures.

Overall, phase change heat sinks can be an effective solution for dissipating heat from electronic devices, particularly in situations where a compact and lightweight heat sink is required. However, their higher cost and potential limitations in certain situations should be considered when choosing a heat sink solution.

4. Vapor-based Heat Sinks

Vapor-based heat sinks are a type of heat dissipation solution that uses a liquid or vapor to transfer heat away from electronic components. This method is also known as a phase change heat sink, and it utilizes the latent heat of vaporization to remove heat from the device.

One advantage of vapor-based heat sinks is their ability to operate in environments where air-based heat sinks may fail. For example, they can be used in high-humidity environments or in situations where the surrounding air is not able to effectively dissipate heat.

However, vapor-based heat sinks can also have some drawbacks. One potential issue is that they may require more maintenance than other types of heat sinks, as the liquid or vapor may need to be replenished or changed periodically. Additionally, there may be safety concerns with using a vapor-based heat sink, as the liquid or vapor may be hazardous if it comes into contact with electronics or other components.

Another potential drawback of vapor-based heat sinks is that they may not be as efficient as other types of heat sinks in certain situations. For example, if the heat sink is not designed properly, it may not be able to effectively transfer heat away from the electronic components, resulting in decreased performance and potentially damage to the device.

Overall, vapor-based heat sinks can be a useful option for certain types of electronic devices, but it is important to carefully consider the pros and cons before deciding if this type of heat sink is appropriate for your needs.

Maximizing Heat Sink Performance

Proper Installation

Proper installation of a heat sink is crucial to maximize its performance. The following are some guidelines to ensure proper installation:

- Surface Preparation

Before installing the heat sink, the surface of the electronic device must be cleaned and prepared. Any dirt, dust, or debris must be removed to ensure that the heat sink makes good contact with the device.

- Application of Thermal Paste

Thermal paste must be applied between the heat sink and the device. The paste helps to fill any gaps and improve the heat transfer between the two surfaces. It is important to apply the paste evenly and in the correct amount to ensure maximum performance.

- Assembly of the Heat Sink

The heat sink must be assembled properly to ensure that it makes good contact with the device. The heat sink must be secured in place using screws or other fasteners. It is important to ensure that the heat sink is not too tight or too loose, as this can affect its performance.

- Alignment of the Heat Sink

The heat sink must be aligned properly to ensure that it makes good contact with the device. The heat sink must be positioned correctly to allow for proper heat transfer.

- Testing of the Heat Sink

After installation, the heat sink must be tested to ensure that it is functioning properly. The temperature of the device must be monitored to ensure that it is within safe operating limits.

Overall, proper installation of a heat sink is critical to ensure that it performs optimally. By following these guidelines, you can ensure that your heat sink is installed correctly and provides the best possible performance.

Maintenance and Cleaning

Regular maintenance and cleaning of heat sinks are crucial to ensure optimal performance. Over time, heat sinks can become dirty and clogged with dust and debris, which can reduce their efficiency and increase the risk of failure. Therefore, it is essential to keep heat sinks clean and well-maintained to ensure that they continue to function effectively.

Here are some tips for maintaining and cleaning heat sinks:

- Shut down the device: Before cleaning the heat sink, it is important to shut down the device and allow it to cool down completely. This will prevent any risk of electric shock or damage to the device.

- Dismantle the heat sink: To clean the heat sink, it may be necessary to dismantle it from the device. This will allow you to access all areas of the heat sink and remove any dust or debris that has accumulated.

- Use compressed air: Compressed air can be used to blow away any dust or debris that has accumulated on the heat sink. It is important to use a clean, dry compressor to avoid moisture buildup.

- Use a brush: A soft-bristled brush can be used to gently remove any loose debris from the heat sink. It is important to avoid using a brush that is too stiff, as this can damage the heat sink.

- Use a vacuum cleaner: A vacuum cleaner can be used to remove any remaining dust or debris from the heat sink. It is important to use a vacuum cleaner with a soft-bristled brush attachment to avoid damaging the heat sink.

- Inspect the heat sink: After cleaning the heat sink, it is important to inspect it for any damage or wear and tear. If any damage is found, it may be necessary to replace the heat sink.

By following these tips, you can ensure that your heat sink continues to function effectively and efficiently. Regular maintenance and cleaning can help to prevent damage and extend the lifespan of your heat sink.

Optimizing Design and Layout

In order to achieve the best possible performance from your heat sink, it is essential to optimize the design and layout of the device. This can be done by taking into account several key factors, including the size and shape of the heat sink, the material it is made from, and the arrangement of fins or other surface enhancements.

Size and Shape

The size and shape of the heat sink are important factors to consider when optimizing its performance. A larger heat sink will generally be able to dissipate more heat, but it may also be more expensive and harder to fit into smaller devices. On the other hand, a smaller heat sink may be more cost-effective and easier to integrate into smaller devices, but it may not be able to dissipate as much heat.

When choosing the size and shape of your heat sink, it is important to consider the specific requirements of your electronic device. For example, if you are building a computer, you will need to consider the size and shape of the CPU and other components, as well as the overall size of the case. If you are building a smartphone, you will need to consider the size and shape of the phone itself, as well as the placement of the various components.

Material

The material that your heat sink is made from can also affect its performance. Some materials, such as copper, are highly conductive and can transfer heat more efficiently than other materials, such as aluminum. However, copper is also more expensive than aluminum, so it may not be the best choice for all applications.

Other factors to consider when choosing the material for your heat sink include its density, thermal conductivity, and cost. It is also important to consider the compatibility of the material with the other components of your electronic device, as some materials may corrode or react with other materials over time.

Fins and Surface Enhancements

Fins and other surface enhancements can help to increase the surface area of the heat sink, which can improve its performance. Fins can also help to increase the airflow over the heat sink, which can further improve its ability to dissipate heat.

When designing the layout of your heat sink, it is important to consider the arrangement of the fins or other surface enhancements. For example, staggered fins may be more effective at dissipating heat than parallel fins, as they provide more surface area without increasing the overall size of the heat sink. It is also important to consider the spacing and thickness of the fins, as well as the overall geometry of the heat sink.

In addition to fins, other surface enhancements that can improve the performance of your heat sink include protrusions, ridges, and textured surfaces. These can all help to increase the surface area of the heat sink and improve its ability to dissipate heat.

Overall, optimizing the design and layout of your heat sink is crucial to achieving the best possible performance from your electronic device. By considering the size and shape of the heat sink, the material it is made from, and the arrangement of fins or other surface enhancements, you can ensure that your heat sink is able to effectively dissipate heat and keep your device running smoothly.

Recap of Key Points

When it comes to maximizing the performance of a heat sink for electronic devices, there are several key points to consider. These include:

- Material: The material used for the heat sink is crucial in determining its effectiveness. Some of the most effective materials for heat sinks include copper, aluminum, and steel. These materials have high thermal conductivity, which means they can transfer heat away from the electronic device quickly and efficiently.

- Fin Design: The design of the fins on the heat sink can also affect its performance. Fins increase the surface area of the heat sink, which allows it to dissipate heat more effectively. However, if the fins are too close together, they can create turbulence that can actually hinder heat dissipation. The ideal fin spacing depends on the specific application and the type of heat sink being used.

- Airflow: Proper airflow is essential for the heat sink to function effectively. If the heat sink is obstructed or there is not enough airflow, it will not be able to dissipate heat as efficiently. This can lead to overheating and damage to the electronic device. It is important to ensure that the heat sink is properly installed and that there is adequate airflow around it.

- Size: The size of the heat sink is also an important factor in its performance. A larger heat sink will have a greater surface area and will be able to dissipate heat more effectively. However, it is important to ensure that the heat sink is not too large, as this can create excessive resistance to airflow and make it less effective.

- Compatibility: Finally, it is important to ensure that the heat sink is compatible with the electronic device it is designed to cool. Different devices have different thermal requirements, and the heat sink must be able to meet those requirements in order to function effectively. It is important to choose a heat sink that is specifically designed for the device in question, or to ensure that any off-the-shelf heat sink is compatible with the device before installing it.

Future Developments in Heat Sink Technology

The development of heat sink technology is an ongoing process, and there are several promising advancements that could significantly improve the performance of heat sinks in the future.

One potential development is the use of nanomaterials in heat sink design. Nanomaterials have unique thermal properties that can enhance heat transfer and reduce thermal resistance. For example, nanoparticles can increase the surface area of a heat sink, allowing for better heat dissipation. Additionally, nanostructures can enhance the thermal conductivity of materials, improving their ability to transfer heat.

Another area of development is the integration of phase change materials (PCMs) into heat sinks. PCMs are materials that can absorb and release heat as they change phase, such as melting or freezing. By incorporating PCMs into a heat sink, the device can more effectively absorb and dissipate heat, improving its overall performance.

Advancements in materials science and manufacturing processes may also lead to the development of new heat sink designs. For example, 3D printing technology could enable the creation of complex, custom heat sink shapes that are optimized for specific applications. Additionally, the use of new materials, such as carbon nanotubes or graphene, could provide improved thermal conductivity and enhanced heat transfer capabilities.

Furthermore, the development of more efficient cooling systems, such as liquid cooling or two-phase cooling, could significantly improve the performance of heat sinks. These systems can provide more efficient heat transfer and enable higher heat dissipation rates, allowing electronic devices to operate more efficiently and effectively.

Overall, the future of heat sink technology holds promise for significant improvements in performance and efficiency. As new materials, manufacturing processes, and cooling systems are developed, heat sinks will become increasingly effective at dissipating heat and improving the performance of electronic devices.

Frequently Asked Questions

- What is the best material for a heat sink?

- Common materials include aluminum, copper, and steel.

- Aluminum is lightweight and widely used due to its cost-effectiveness.

- Copper has better thermal conductivity but is more expensive.

- Steel is heavy but can provide good strength and durability.

- How do I choose the right size of heat sink for my device?

- Determine the maximum amount of heat your device generates.

- Check the thermal resistance (R-theta) rating of your device.

- Choose a heat sink with a thermal resistance lower than your device’s rating.

- Use a calculator or software to determine the required surface area.

- How important is the shape of a heat sink?

- Shape affects airflow and heat dissipation.

- Fin-type heat sinks are effective for small devices.

- Larger heat sinks can use multiple fins or a single extrusion.

- Cylindrical heat sinks can be effective for low-profile devices.

- Can I use multiple heat sinks for a single device?

- Yes, this can improve heat dissipation.

- Spread the heat sinks evenly around the device.

- Use thermal pads or interface material between the heat sinks and device.

- How do I attach a heat sink to my device?

- Use thermal adhesive or thermal pads.

- Apply even pressure during assembly.

- Allow the adhesive to cure before applying power.

- Can I use liquid cooling instead of a heat sink?

- Yes, liquid cooling can be more effective for high-performance devices.

- Custom liquid cooling systems can be complex and expensive.

- Pre-made liquid cooling systems are available for some devices.

- How do I maintain my heat sink?

- Keep the heat sink clean and free of dust buildup.

- Check for any loose components or damage.

- Reapply thermal adhesive or interface material as needed.

Q1: How do heat sinks work?

A heat sink is a passive heat transfer device that transfers heat from a hot surface to a cooler surface. The main purpose of a heat sink is to reduce the temperature of electronic components and circuits by dissipating the excess heat generated by them. The heat sink works by increasing the surface area of the hot component in contact with the heat sink, which allows for more efficient heat transfer.

The heat sink consists of a metal or plastic body with a large surface area that is in contact with the hot component. The heat sink may also have fins or other protrusions that increase the surface area for heat transfer. The heat sink is typically made of materials with high thermal conductivity, such as copper or aluminum, which allow for efficient heat transfer.

When the heat sink is in contact with the hot component, the heat generated by the component is transferred to the heat sink. The heat sink then transfers this heat to the surrounding air through convection and radiation. The rate of heat transfer is dependent on the temperature difference between the hot component and the heat sink, as well as the thermal conductivity and surface area of the heat sink.

The efficiency of a heat sink depends on its design and the thermal conductivity of the materials used. In addition, the airflow around the heat sink also affects its performance. A well-designed heat sink with good airflow can be highly effective at dissipating heat from electronic components.

Q2: Can I use any heat sink with my electronic device?

When it comes to selecting a heat sink for your electronic devices, it’s important to consider compatibility. The question of whether you can use any heat sink with your device is not a straightforward one, as different devices require different types of heat sinks.

In general, heat sinks are designed to fit specific devices based on their size, shape, and mounting options. Some heat sinks are designed to be universal, while others are designed for specific devices or device families. For example, a heat sink designed for a specific CPU may not fit or perform well on a different CPU with a different form factor.

Additionally, the thermal requirements of different devices can vary significantly. A heat sink that is sufficient for one device may not be enough for another device with higher thermal requirements. Therefore, it’s important to select a heat sink that is specifically designed for your device or device family to ensure optimal performance.

It’s also worth noting that not all heat sinks are created equal in terms of performance. Some heat sinks are designed to be more effective than others, and may be able to dissipate more heat for a given form factor. When selecting a heat sink, it’s important to consider both compatibility and performance, and to choose a heat sink that is appropriate for your specific needs.

Q3: What is the best material for a heat sink?

When it comes to choosing the best material for a heat sink, there are several factors to consider. The most important factor is the thermal conductivity of the material. Thermal conductivity is the ability of a material to conduct heat. The higher the thermal conductivity of a material, the better it is at dissipating heat.

Some of the most common materials used for heat sinks include aluminum, copper, and thermal grease. Aluminum is a popular choice because it is lightweight and inexpensive. It also has a relatively high thermal conductivity, making it a good choice for many applications.

Copper, on the other hand, has an even higher thermal conductivity than aluminum. This makes it a popular choice for high-performance heat sinks. Copper is also a good choice for applications where weight is not a concern, as it is more expensive than aluminum.

Thermal grease is a type of paste that is applied to the surface of a heat sink. It helps to fill in any gaps between the heat sink and the component being cooled, improving the thermal conductivity between the two. Thermal grease is often used in conjunction with heat sinks made of materials like aluminum or copper.

Ultimately, the best material for a heat sink will depend on the specific application and the requirements of the device being cooled. It is important to carefully consider the thermal conductivity and other properties of the material to ensure that it is capable of effectively dissipating heat.

Q4: How do I know if my electronic device needs a heat sink?

If you’re wondering whether your electronic device needs a heat sink, there are several signs to look out for. Here are some key indicators that your device may benefit from a heat sink:

- High temperatures: If your device is running very hot to the touch, it may be overheating and in need of a heat sink to dissipate excess heat.

- Reduced performance: If your device is running slower than usual or experiencing crashes or freezes, it may be overheating and in need of a heat sink to improve performance.

- Fan noise: If your device’s fan is running constantly or loudly, it may be trying to dissipate excess heat and could benefit from a heat sink to help regulate temperatures.

- Physical damage: If your device has been physically damaged or has sustained burns or other damage due to overheating, it may need a heat sink to prevent further damage.

If you’re unsure whether your device needs a heat sink, it’s always a good idea to consult the manufacturer’s guidelines or seek the advice of a professional technician. They can help you determine whether a heat sink is necessary and recommend the best type of heat sink for your specific device.

Q5: Can I make my own heat sink?

If you are a DIY enthusiast or a person who likes to customize things, then making your own heat sink can be an interesting project. However, before you start, it is important to understand that designing and fabricating a heat sink requires specialized knowledge and skills. Therefore, it is not recommended for someone who lacks experience in this area.

That being said, if you are determined to make your own heat sink, there are a few things you should keep in mind. Firstly, the design of the heat sink should be such that it can efficiently dissipate heat from the electronic device. This means that the heat sink should have a large surface area and should be made of a material that has a high thermal conductivity.

Another important factor to consider is the shape and size of the heat sink. The heat sink should be big enough to accommodate the electronic device, but not so large that it is impractical to use. Additionally, the shape of the heat sink should be such that it can effectively dissipate heat in all directions.

It is also important to consider the type of thermal interface material (TIM) that you will use between the heat sink and the electronic device. TIMs are used to fill any gaps between the two surfaces and improve the thermal conductivity between them. Different TIMs have different thermal conductivities and can be used for different applications.

Finally, it is important to test the heat sink to ensure that it is working effectively. This can be done using thermal simulation software or by measuring the temperature of the electronic device before and after installing the heat sink.

In summary, while making your own heat sink can be an interesting project, it requires specialized knowledge and skills. If you are not experienced in this area, it is recommended to purchase a pre-made heat sink.

FAQs

1. What is a heat sink?

A heat sink is a passive heat exchanger that transfers heat generated by an electronic device to the surrounding environment. It is typically composed of a metal base and one or more fins or fins stacks, which increase the surface area for heat dissipation. The primary function of a heat sink is to reduce the temperature of the device by dissipating the excess heat generated during operation.

2. Why is a heat sink necessary for electronic devices?

Electronic devices, such as processors, power electronics, and LED lights, generate heat during operation. This heat can cause the device to malfunction or even fail if not properly dissipated. A heat sink helps to remove the excess heat from the device, ensuring that it operates within safe temperature limits and extends its lifespan.

3. What factors should be considered when choosing a heat sink?

When selecting a heat sink for an electronic device, several factors should be considered. These include the device’s thermal requirements, the heat sink’s material and design, the mounting method, and the available space for installation. It is also essential to consider the device’s maximum operating temperature and the heat sink’s thermal resistance (Rth) to ensure that it can effectively dissipate the heat generated by the device.

4. What are the different types of heat sinks?

There are several types of heat sinks, including extruded, bent-fin, folded-fin, and direct-to-fan. Extruded heat sinks are typically made of aluminum and have a simple, straightforward design. Bent-fin heat sinks have fins that are bent at a 90-degree angle, providing a larger surface area for heat dissipation. Folded-fin heat sinks have fins that are folded back and forth, creating a more compact design. Direct-to-fan heat sinks have a built-in fan that draws air over the fins, providing active cooling.

5. How do I install a heat sink on my electronic device?

The installation process for a heat sink will vary depending on the specific device and heat sink. Generally, heat sinks are installed using screws, clips, or thermal tape. It is important to follow the manufacturer’s instructions for proper installation to ensure effective heat dissipation and prevent damage to the device.

6. Can a heat sink be used for multiple devices?

In some cases, a heat sink can be used for multiple devices. However, it is important to consider the thermal requirements of each device and ensure that the heat sink can effectively dissipate the heat generated by all of the devices. If multiple devices are connected to a single heat sink, it is important to properly mount and secure each device to the heat sink to ensure proper heat dissipation.