A heat sink is a critical component in thermal management systems, responsible for dissipating excess heat generated by electronic devices. It is designed to transfer heat from the source to the surrounding environment, ensuring that the device operates within safe temperature limits. Heat sinks come in various shapes and sizes, and they are used in a wide range of applications, from small consumer electronics to large industrial equipment. Understanding the function of a heat sink is essential for effective thermal management, and this article will explore the role of heat sinks in detail.

A heat sink is a passive thermal management component that is used to dissipate heat generated by electronic components. Its primary function is to transfer heat from the component to the surrounding environment, thus preventing overheating and ensuring proper operation of the device. The heat sink works by increasing the surface area available for heat transfer through fins, flutes or other surface enhancements. The heat sink also promotes natural convection and/or forced airflow to increase heat transfer efficiency. In addition, heat sinks can be made of materials with high thermal conductivity, such as copper or aluminum, to facilitate heat transfer. Overall, the function of a heat sink is to maintain the temperature of electronic components within safe operating limits, thereby ensuring their reliability and longevity.

What is a Heat Sink?

Definition and Purpose

A heat sink is a passive heat transfer device that is used to dissipate heat generated by electronic components in electronic devices. The primary function of a heat sink is to provide a large surface area for heat to transfer from the electronic component to the surrounding environment. This helps to prevent overheating and improve the overall performance and reliability of the electronic device.

In simpler terms, a heat sink is a metal component that is designed to absorb heat generated by the electronic components and dissipate it to the surrounding environment. The heat sink works by increasing the surface area available for heat transfer, which increases the rate at which heat can be dissipated. This helps to maintain a safe operating temperature for the electronic components and prevent damage caused by overheating.

The importance of heat sinks in electronic devices cannot be overstated. Without an effective heat sink, electronic components can become dangerously hot, leading to reduced performance, decreased reliability, and even failure. Heat sinks are used in a wide range of electronic devices, including computers, servers, smartphones, and other consumer electronics.

Overall, the purpose of a heat sink is to ensure that electronic devices operate at safe and optimal temperatures, which is essential for maintaining their performance and longevity.

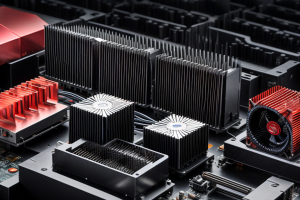

Types of Heat Sinks

When it comes to dissipating heat from electronic components, heat sinks play a crucial role. They are passive or active devices that help to transfer heat away from the component and into the surrounding environment. In this section, we will discuss the different types of heat sinks.

Passive Heat Sinks

Passive heat sinks are the most common type of heat sink used in electronic devices. They are designed to dissipate heat by using natural convection and radiation. Passive heat sinks can be made from a variety of materials, including aluminum, copper, and silicon. They are typically designed with fins or other protrusions to increase the surface area available for heat transfer. Passive heat sinks are often used in small electronic devices, such as smartphones and laptops.

Active Heat Sinks

Active heat sinks use fans or other mechanical means to force air over the heat-generating component. This increases the rate of heat transfer and helps to keep the component cooler. Active heat sinks are often used in larger electronic devices, such as servers and power supplies. They can also be used in smaller devices when a higher level of cooling is required.

Hybrid Heat Sinks

Hybrid heat sinks combine the principles of passive and active heat sinks. They use fins or other passive cooling mechanisms to dissipate heat, but also include a fan or other active cooling mechanism to enhance the rate of heat transfer. Hybrid heat sinks are often used in larger electronic devices, such as high-performance computers and gaming consoles. They can provide a balance between the benefits of both passive and active cooling methods.

How Does a Heat Sink Work?

Thermal Conductivity

- Definition of Thermal Conductivity:

Thermal conductivity is the ability of a material to conduct heat. It is a measure of how well a material conducts heat in relation to its density and composition. Materials with high thermal conductivity have the ability to transfer heat efficiently from one point to another. - How it relates to Heat Sinks:

Heat sinks are designed to dissipate heat generated by electronic components and devices. The thermal conductivity of the material used in the heat sink plays a crucial role in its ability to dissipate heat effectively. Materials with high thermal conductivity, such as copper and aluminum, are commonly used in heat sink designs as they are able to transfer heat quickly and efficiently. The thermal conductivity of the material is also affected by the surface area and shape of the heat sink, as well as the type of heat sink design used. A heat sink with a large surface area and a design that maximizes contact between the heat sink and the electronic component will be more effective at dissipating heat.

Heat Transfer

Heat transfer is the process by which heat is transferred from one object to another due to a temperature difference. It is an essential concept in understanding the function of a heat sink. There are three types of heat transfer: conduction, convection, and radiation.

Conduction is the transfer of heat through direct contact between two objects. In a heat sink, conduction occurs when the heat generated by the component is transferred to the heat sink. The heat sink’s material must have a high thermal conductivity to facilitate this transfer efficiently.

Convection is the transfer of heat through the movement of a fluid, such as air or water. In a heat sink, convection occurs when the fluid comes into contact with the heat sink’s surface and absorbs the heat. This type of heat transfer is crucial in natural convection, where the fluid moves due to density changes caused by the heat absorption.

Radiation is the transfer of heat through electromagnetic waves. In a heat sink, radiation occurs when the heat generated by the component radiates into the surrounding environment. This type of heat transfer is essential in infrared radiation, where the heat sink absorbs the radiation and transfers the heat to the surrounding environment.

A heat sink facilitates heat transfer by providing a large surface area for the fluid to come into contact with and absorb the heat. Additionally, the heat sink’s material and design must be carefully chosen to maximize the efficiency of heat transfer. By efficiently transferring heat, a heat sink helps to maintain a safe operating temperature for the component it is attached to, preventing overheating and failure.

Heat Dissipation

Definition of Heat Dissipation

Heat dissipation refers to the process of transferring heat generated by electronic devices to the surrounding environment. This heat can accumulate due to various reasons, such as the operation of electronic components, conversion of electrical energy into useful work, or loss of energy due to inefficiencies in the system.

Importance of Heat Dissipation in Electronic Devices

Electronic devices generate heat as a byproduct of their operation. This heat can cause the device to malfunction or even fail catastrophically if not properly dissipated. In addition, excessive heat can reduce the lifespan of electronic components and decrease their overall performance. Therefore, it is crucial to ensure that electronic devices have adequate heat dissipation mechanisms to prevent overheating and ensure proper functioning.

How Heat Sinks Aid in Heat Dissipation

Heat sinks are passive components that aid in heat dissipation by providing a large surface area for heat transfer to the surrounding environment. They are typically made of materials with high thermal conductivity, such as copper or aluminum, which facilitate the transfer of heat from the electronic components to the heat sink. The heat sink then transfers the heat to the surrounding air through convection or radiation.

In addition to providing a large surface area, heat sinks also have fins or channels that increase the surface area for heat transfer. These fins or channels increase the contact area between the heat sink and the surrounding air, which enhances the rate of heat transfer.

Furthermore, heat sinks can be designed to actively aid in heat dissipation. For example, they can be fitted with fans or blowers that force air to flow over the heat sink, thereby increasing the rate of heat transfer. These active heat sinks are commonly used in high-performance computing systems and other applications where heat dissipation is critical.

Overall, heat sinks play a crucial role in ensuring that electronic devices operate safely and efficiently by providing an effective means of heat dissipation.

Heat Sink Design

When designing a heat sink, there are several factors that must be considered. These include the type of device or component that the heat sink will be used with, the amount of heat that needs to be dissipated, and the size and shape of the heat sink.

The type of heat sink design used will depend on the specific application and the requirements of the device or component. There are several types of heat sink designs, including:

- Air-cooled heat sinks: These heat sinks rely on the circulation of air to dissipate heat. They are commonly used in small devices and electronic components.

- Liquid-cooled heat sinks: These heat sinks use a liquid coolant to dissipate heat. They are commonly used in larger devices and high-performance computing systems.

- Phase-change heat sinks: These heat sinks use a coolant that changes phase (e.g. melts or boils) to dissipate heat. They are commonly used in high-power applications, such as automotive engines and industrial equipment.

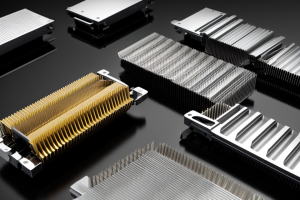

The materials used in heat sink design are also important considerations. Common materials used in heat sink design include aluminum, copper, and heat-resistant plastics. The choice of material will depend on factors such as cost, weight, and thermal conductivity.

In addition to these factors, the layout and design of the heat sink itself can also affect its performance. This includes the shape and size of the heat sink, as well as the arrangement of fins or other heat-dissipating features.

Overall, the design of a heat sink is a critical factor in its ability to effectively dissipate heat and prevent overheating in electronic devices and components.

Applications of Heat Sinks

Electronic Devices

In today’s world, electronic devices are an integral part of our daily lives. From computers to smartphones, servers to lighting systems, these devices generate a significant amount of heat during operation. This heat can cause the device to malfunction or even catch fire if not properly dissipated. This is where heat sinks come into play.

Heat sinks are passive devices that help to dissipate heat generated by electronic devices. They are typically made of metal and have a large surface area that allows for efficient heat transfer. By increasing the surface area of the device, heat can be spread out over a larger area, which helps to lower the temperature of the device.

One of the most common applications of heat sinks is in computers. The central processing unit (CPU) and graphics processing unit (GPU) are two of the most important components in a computer that generate a significant amount of heat. A heat sink is typically mounted on top of these components to dissipate the heat generated by them. This helps to keep the computer running smoothly and prevents it from overheating.

Smartphones are another example of electronic devices that benefit from the use of heat sinks. The battery, processor, and other components of a smartphone generate heat during operation. This heat can cause the device to become unstable or even shut down. By using a heat sink, the heat generated by these components can be dissipated, which helps to keep the device running smoothly.

Servers are another example of electronic devices that rely heavily on heat sinks. Servers are used to store and process large amounts of data, which generates a significant amount of heat. Heat sinks are used to dissipate this heat, which helps to prevent the server from overheating and shutting down.

Finally, lighting systems also benefit from the use of heat sinks. LED lights, in particular, generate a significant amount of heat during operation. This heat can cause the LED to fail prematurely or even catch fire. By using a heat sink, the heat generated by the LED can be dissipated, which helps to prolong its lifespan and prevent it from catching fire.

In conclusion, heat sinks play a critical role in the proper functioning of electronic devices. By dissipating the heat generated by these devices, heat sinks help to prevent them from overheating, shutting down, or even catching fire.

Automotive Industry

The automotive industry is one of the primary consumers of heat sinks, as they play a critical role in engine cooling systems, HVAC systems, and electric vehicle cooling systems. In modern vehicles, the engine produces a significant amount of heat that can cause damage to other components if not properly dissipated. This is where heat sinks come in, as they help to transfer heat away from the engine and other critical components, ensuring optimal performance and longevity.

One of the most common applications of heat sinks in the automotive industry is in engine cooling systems. The engine produces a large amount of heat during operation, and this heat needs to be dissipated to prevent overheating and damage to the engine. Heat sinks are used to transfer heat away from the engine, which helps to keep the engine running at optimal temperatures. They are typically made of materials such as aluminum or copper, which have high thermal conductivity, allowing them to efficiently transfer heat.

Another application of heat sinks in the automotive industry is in HVAC systems. Heat sinks are used to cool the compressor and other components of the air conditioning system, which helps to maintain optimal performance and efficiency. They are also used in electric vehicle cooling systems, where they help to cool the battery pack and other critical components, ensuring that they operate at optimal temperatures.

Overall, heat sinks play a critical role in the automotive industry, as they help to ensure that engines and other components operate at optimal temperatures, which can improve performance and longevity.

Industrial Applications

Heat sinks find extensive use in various industrial applications due to their ability to efficiently dissipate heat. Some of the most common industrial applications of heat sinks are:

- HVAC Systems: Heat sinks are extensively used in HVAC (Heating, Ventilation, and Air Conditioning) systems. In these systems, heat sinks are used to dissipate heat generated by the compressors, which are a vital component of the system. The heat sinks help maintain the temperature of the compressors within safe limits, thereby preventing damage to the system.

- Power Generation Systems: Heat sinks are also used in power generation systems, such as gas turbines and diesel generators. These systems generate a significant amount of heat during operation, which needs to be dissipated to maintain the system’s efficiency. Heat sinks help in dissipating this heat, thereby preventing overheating and ensuring smooth operation of the system.

- Manufacturing Processes: Heat sinks are used in various manufacturing processes, such as molding and casting. In these processes, heat is generated due to friction and chemical reactions. Heat sinks help in dissipating this heat, thereby preventing the buildup of heat and ensuring the safety of the workers and the quality of the final product.

Overall, heat sinks play a critical role in maintaining the efficiency and safety of various industrial processes. Their ability to dissipate heat effectively makes them an essential component in many industrial applications.

Benefits of Using Heat Sinks

Improved Performance

Using a heat sink is beneficial for improving the performance of electronic devices. One of the most significant advantages of using a heat sink is that it reduces the risk of overheating. Overheating can cause permanent damage to electronic components and reduce the lifespan of the device. By dissipating excess heat away from the device, a heat sink helps to prevent this damage and ensure that the device operates within safe temperature ranges.

In addition to reducing the risk of overheating, a heat sink can also increase the lifespan of electronic devices. By keeping the device cooler, a heat sink can help to extend the lifespan of the device by reducing the rate of degradation of the electronic components. This can be particularly important in applications where the device is expected to operate for extended periods of time or in harsh environments.

Finally, using a heat sink can also improve the performance of the device. By ensuring that the device operates within safe temperature ranges, a heat sink can help to prevent thermal throttling, which can occur when the device becomes too hot and reduces its performance to prevent damage. This can help to ensure that the device operates at its maximum potential, providing better performance and longer lifespan.

Cost Savings

Using heat sinks in electronic devices can provide significant cost savings in the long run. Here are some of the ways in which heat sinks can help reduce costs:

- Reduced risk of device failure: When electronic devices become too hot, they are at risk of failure. This can result in costly repairs or replacements. By using a heat sink to dissipate heat, the risk of device failure is reduced, leading to cost savings.

- Lower energy consumption: Electronic devices that run too hot may require more energy to operate. This can lead to higher energy bills and a reduced efficiency of the device. By using a heat sink to keep the device cooler, it can operate more efficiently, leading to lower energy consumption and cost savings.

- Lower maintenance costs: When electronic devices become too hot, they may require more frequent maintenance or repairs. This can be costly and time-consuming. By using a heat sink to keep the device cooler, maintenance costs can be reduced, leading to cost savings over time.

Environmental Impact

Using heat sinks has a significant positive impact on the environment in several ways:

- Reduced e-waste: Electronic devices generate heat during operation, which can cause damage to the components if not dissipated properly. Without a heat sink, these devices may fail prematurely, leading to electronic waste. By using heat sinks, the lifespan of electronic devices can be extended, reducing the amount of e-waste generated.

- Energy efficiency: When electronic devices operate efficiently, they consume less energy. Heat sinks help maintain efficient operation by dissipating heat, allowing the devices to run cooler and use less power. This leads to energy savings and reduces the overall carbon footprint of the device.

- Lower carbon footprint: The manufacturing process of electronic devices requires a significant amount of energy and resources. By using heat sinks to extend the lifespan of these devices, the need for frequent replacement is reduced, leading to a lower carbon footprint. Additionally, the use of heat sinks can reduce the overall energy consumption of electronic devices, leading to a lower carbon footprint over their lifetime.

FAQs

1. What is a heat sink?

A heat sink is a passive heat exchanger that transfers heat from one medium to another. It is commonly used in electronics to dissipate heat generated by components such as processors, power electronics, and LEDs. A heat sink is typically made of metal and has a large surface area to increase its thermal conductivity.

2. What is the function of a heat sink?

The primary function of a heat sink is to dissipate heat generated by electronic components. It transfers heat from the component to the surrounding environment, allowing the component to operate within safe temperature limits. Heat sinks are commonly used in computers, servers, and other electronic devices to prevent overheating and ensure reliable operation.

3. How does a heat sink work?

A heat sink works by increasing the surface area of the component that is in contact with the surrounding air. This increases the rate of heat transfer from the component to the air, which helps to dissipate the heat. Heat sinks are typically designed with fins or other structures that increase the surface area and improve the flow of air over the component. In some cases, heat sinks may also use liquid cooling systems to transfer heat away from the component.

4. What are the benefits of using a heat sink?

The benefits of using a heat sink include improved reliability, longer lifespan, and better performance of electronic components. By dissipating heat, a heat sink can prevent overheating and thermal damage to components, which can lead to failure or reduced performance. Heat sinks can also help to reduce noise levels by reducing the need for fans or other cooling systems that generate noise.

5. How do I choose the right heat sink for my application?

Choosing the right heat sink for your application depends on several factors, including the power rating of the component, the ambient temperature of the surrounding environment, and the desired thermal performance. It is important to consult with a thermal engineer or other expert to determine the appropriate size and type of heat sink for your specific application.