Effective cooling is essential for the smooth functioning of electronic devices. One of the key components that help in cooling is a heat sink. A heat sink is a metal component that is used to dissipate heat from electronic devices. But is a heat sink necessary for effective cooling? In this article, we will explore the role of heat sinks in cooling and determine whether they are necessary for efficient heat dissipation. We will also discuss the factors that affect the effectiveness of heat sinks and how they can be improved. So, let’s dive in to explore the world of heat sinks and cooling.

A heat sink is a passive heat exchanger that is used to dissipate heat generated by an electronic component or device. While a heat sink can be effective in improving the thermal performance of a system, it is not always necessary for effective cooling. The effectiveness of a heat sink depends on several factors, including the size and shape of the heat sink, the thermal conductivity of the materials used, and the surface area of the heat sink in contact with the component or device being cooled. In some cases, other cooling methods such as forced air cooling or liquid cooling may be more effective than using a heat sink. Ultimately, the decision to use a heat sink for cooling will depend on the specific requirements of the system and the type of cooling method that is being used.

What is a Heat Sink?

Definition and Function

A heat sink is a passive or active device that is used to dissipate heat generated by an electronic component or system. It is an essential component in many electronic devices, particularly those that generate significant amounts of heat, such as processors, power electronics, and LED lights. The primary function of a heat sink is to transfer heat from the source to the surrounding environment, thereby reducing the temperature of the component or system.

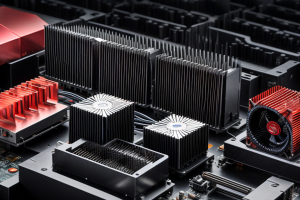

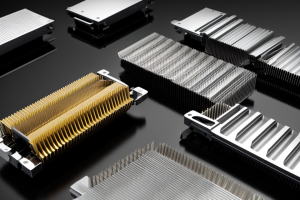

Heat sinks come in various shapes and sizes, and they can be made from different materials, including aluminum, copper, and thermally conductive plastics. The choice of material depends on the specific application and the thermal requirements of the component or system. Heat sinks can be designed to dissipate heat in a variety of ways, including natural convection, forced convection, and radiation.

In natural convection, heat is dissipated through the movement of air molecules. Heat sinks designed for natural convection are typically fin-based, with the fins providing a large surface area for air to flow over and carry away heat. In forced convection, a fan is used to force air over the heat sink, increasing the rate of heat dissipation. Heat sinks designed for forced convection are typically larger and more complex, with multiple fins and channels to direct airflow.

Radiation is another method of heat dissipation, and it is often used in conjunction with convection. Heat sinks designed for radiation typically have highly reflective surfaces, which help to direct heat energy into the surrounding environment.

Overall, the function of a heat sink is to provide an efficient and reliable means of dissipating heat from electronic components and systems. Without a heat sink, the temperature of the component or system can rise to dangerous levels, leading to reduced performance, increased failure rates, and even catastrophic failure.

Importance of Heat Sinks

Heat sinks are passive thermal management components that are used to dissipate heat generated by electronic devices. They are commonly used in electronic circuits and are designed to absorb and dissipate heat from components such as transistors, diodes, and other semiconductor devices. The importance of heat sinks in effective cooling cannot be overstated.

One of the primary reasons why heat sinks are necessary is to prevent overheating of electronic components. When electronic devices generate heat, it can cause the device to malfunction or even fail completely. By using a heat sink, the heat generated by the device can be transferred to the surrounding environment, preventing the device from overheating.

In addition to preventing overheating, heat sinks also play a critical role in improving the overall performance of electronic devices. When electronic components become too hot, their performance can be adversely affected. This can result in slower processing times, reduced efficiency, and even permanent damage to the device. By using a heat sink, the temperature of the electronic components can be maintained within safe operating limits, ensuring optimal performance.

Heat sinks are also beneficial in terms of their size and weight. They are relatively small and lightweight, making them easy to integrate into electronic devices. This makes them an ideal solution for applications where space is limited or weight is a critical factor.

Overall, the importance of heat sinks in effective cooling cannot be overstated. They are essential for preventing overheating, maintaining optimal performance, and ensuring the longevity of electronic devices. Whether used in small consumer electronics or large industrial applications, heat sinks play a critical role in thermal management.

When is a Heat Sink Necessary?

Factors Affecting the Need for a Heat Sink

When it comes to determining whether a heat sink is necessary for effective cooling, there are several factors that must be considered. These factors include power dissipation, environmental conditions, and design considerations.

Power Dissipation

The first factor to consider is the power dissipation of the electronic component or device that requires cooling. The more power a component or device consumes, the more heat it generates. Therefore, if the power dissipation is high, a heat sink is likely necessary to ensure effective cooling.

Environmental Conditions

The environmental conditions in which the electronic component or device operates also play a significant role in determining whether a heat sink is necessary. For example, if the device is used in a high-temperature environment, such as in a car engine, a heat sink may be necessary to prevent overheating. On the other hand, if the device is used in a low-temperature environment, such as in a refrigerator, a heat sink may not be necessary.

Design Considerations

Finally, the design of the electronic component or device is also a critical factor to consider when determining whether a heat sink is necessary. If the device is designed with heat dissipation in mind, such as by incorporating heat sinks or using efficient cooling mechanisms, a heat sink may not be necessary. However, if the device is not designed with heat dissipation in mind, a heat sink may be necessary to ensure effective cooling.

In summary, the need for a heat sink for effective cooling depends on several factors, including power dissipation, environmental conditions, and design considerations. Understanding these factors can help determine whether a heat sink is necessary for a particular electronic component or device.

Common Scenarios Requiring a Heat Sink

In certain situations, a heat sink is an indispensable component for effective cooling. Some common scenarios where a heat sink is necessary include:

Electronic Devices

Electronic devices, such as computers, servers, and smartphones, generate a significant amount of heat during operation. This heat can cause the device to overheat, leading to reduced performance, shortened lifespan, and even device failure. A heat sink is used to dissipate this excess heat, ensuring that the device operates within safe temperature limits.

Industrial Processes

In industrial processes, such as manufacturing and chemical processing, heat is often generated as a byproduct of the process. This heat can pose a risk to equipment and personnel, as well as affect the quality of the final product. A heat sink is used to transfer this heat away from the process, preventing overheating and ensuring consistent product quality.

Automotive Applications

In automotive applications, such as engines and transmissions, heat is generated as a result of friction and combustion. This heat can cause the components to overheat, leading to reduced performance and reliability. A heat sink is used to dissipate this excess heat, ensuring that the components operate within safe temperature limits and maintain their performance over time.

How to Choose the Right Heat Sink?

Key Specifications to Consider

When selecting a heat sink for effective cooling, there are several key specifications to consider. These include:

- Thermal resistance: Thermal resistance, also known as R-value, is a measure of a material’s ability to resist heat flow. A lower thermal resistance indicates better insulation, and therefore, a better ability to resist heat flow. When selecting a heat sink, it is important to consider the thermal resistance of the material to ensure that it can effectively dissipate heat.

- Material compatibility: The material used in the heat sink should be compatible with the components it is designed to cool. For example, if the heat sink will come into contact with electrical components, it should be made of a non-conductive material to prevent short circuits. Additionally, the material should be resistant to corrosion and have a low coefficient of thermal expansion to minimize the risk of thermal stress and mechanical failure.

- Size and shape: The size and shape of the heat sink are also important considerations. The heat sink should be large enough to dissipate the heat generated by the components it is designed to cool. The shape of the heat sink can also affect its performance, with more complex shapes allowing for better heat dissipation. Additionally, the heat sink should be mechanically compatible with the components it is designed to cool, with adequate clearance to allow for proper airflow.

Factors Affecting Heat Sink Performance

Airflow

When it comes to choosing the right heat sink, one of the most important factors to consider is airflow. The amount of air that is able to flow over the heat sink plays a crucial role in its ability to dissipate heat effectively. It is important to note that increasing the airflow will not necessarily improve the heat sink’s performance if the other factors are not also optimized.

Surface area

Another key factor that affects the performance of a heat sink is its surface area. The larger the surface area of the heat sink, the more effectively it can dissipate heat. This is because a larger surface area allows for more heat to be transferred to the surrounding air.

Heat sink design

The design of the heat sink is also an important factor to consider. A well-designed heat sink will have a larger surface area and will be optimized to maximize airflow. Additionally, the shape of the heat sink can also affect its performance. For example, a heat sink with a larger base will be more stable and will be able to dissipate heat more effectively than a heat sink with a smaller base.

Overall, choosing the right heat sink is crucial for effective cooling. It is important to consider all of the factors that affect heat sink performance, including airflow, surface area, and design, in order to make the best choice for your specific needs.

How to Install a Heat Sink?

Step-by-Step Guide

Preparing the Components

Before installing a heat sink, it is important to prepare the components that will be attached to it. This includes cleaning the CPU and applying thermal paste to the CPU’s heat spreader. The thermal paste will help to improve the contact between the CPU and the heat sink, allowing for more efficient cooling.

Installing the Heat Sink

Once the components are prepared, the next step is to install the heat sink onto the CPU. Start by attaching the heat sink’s mounting bracket to the motherboard using the provided screws. Carefully align the heat sink over the CPU, ensuring that it is centered and the fins are pointing downwards. Gently lower the heat sink onto the CPU, taking care not to apply too much pressure.

Securing the Heat Sink

After the heat sink is installed, it is important to secure it in place to prevent any movement or vibrations. This can be done by attaching the heat sink’s fan to the motherboard using the provided screws. Make sure that the fan is properly aligned with the heat sink and is not obstructed by any other components. Additionally, ensure that the heat sink’s brackets are secured to the motherboard, providing stability and support.

With the heat sink installed and secured, the system is now ready for testing to ensure that the cooling system is functioning properly. It is important to monitor the temperatures of the CPU and other components to ensure that they are within safe operating limits.

Best Practices for Effective Cooling

Proper thermal paste application

- Importance of thermal paste: Thermal paste is a critical component in the heat sink installation process, as it fills the gaps between the heat sink and the CPU, providing efficient heat transfer.

- Thermal conductivity: The thermal paste must have high thermal conductivity to facilitate the transfer of heat from the CPU to the heat sink.

- Applying the paste: Apply a pea-sized amount of thermal paste onto the CPU’s thermal interface material (TIM) before installing the heat sink.

Ensuring proper contact between components

- Close contact: The heat sink must make close contact with the CPU and other components to dissipate heat effectively.

- Pressure: Apply even pressure to the heat sink during installation to ensure proper contact between the components.

- Tightening screws: Tighten the screws securing the heat sink evenly to maintain the close contact between the components.

Minimizing obstructions to airflow

- Airflow: Unobstructed airflow is crucial for effective heat dissipation.

- Fan placement: Position the fans to blow air directly onto the heat sink and other components, promoting efficient heat dissipation.

- Cable management: Properly manage cables to prevent them from obstructing airflow around the heat sink and other components.

FAQs

1. What is a heat sink?

A heat sink is a passive heat exchanger that is used to transfer heat from one device to another. It is typically used to cool electronic components, such as processors and other high-powered devices, by dissipating the heat generated by these components.

2. Why is a heat sink necessary?

A heat sink is necessary because many electronic devices generate a significant amount of heat during operation. This heat can cause the device to overheat, which can lead to decreased performance, reduced lifespan, and even failure. By using a heat sink, the heat generated by the device can be dissipated, keeping the device at a safe temperature.

3. How does a heat sink work?

A heat sink works by using a large surface area to dissipate heat. The heat sink is typically made of a material with a high thermal conductivity, such as copper or aluminum, which allows it to transfer heat efficiently. The heat sink is placed in contact with the device that generates heat, and a fan or other cooling mechanism is used to blow air over the heat sink, carrying away the heat.

4. What are the benefits of using a heat sink?

The benefits of using a heat sink include improved performance, increased lifespan, and reduced risk of failure. By keeping the device at a safe temperature, the heat sink can prevent the device from overheating, which can lead to decreased performance and reduced lifespan. In addition, using a heat sink can also improve the overall reliability of the device.

5. Are there any drawbacks to using a heat sink?

One potential drawback to using a heat sink is that it can be relatively expensive and may require additional space in the device. In addition, a heat sink may also be difficult to install, especially in smaller devices. However, these drawbacks are typically outweighed by the benefits of using a heat sink to keep the device at a safe temperature.