Are you curious about the properties of water and how it behaves when subjected to heat? The concept of heat sinks is often discussed in the context of thermodynamics and heat transfer, but what exactly does it mean for water to be a heat sink? In this article, we will explore the intriguing question of whether water can act as a heat sink and delve into the science behind this phenomenon. Join us as we uncover the fascinating world of thermodynamics and discover the answers to some of the most intriguing questions about the behavior of water and heat. Get ready to be captivated by the mysteries of science!

No, water is not considered a heat sink. A heat sink is a device or material that absorbs and dissipates heat, typically used in thermal management applications. While water can absorb and transport heat, it is not as effective as other materials commonly used as heat sinks, such as metals. This is because water has a relatively low thermal conductivity compared to metals, which means it takes longer for heat to transfer through water. Additionally, water can also corrode and damage materials over time, making it less suitable for use as a heat sink in some applications.

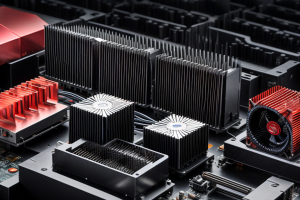

What is a Heat Sink?

Definition and Function

A heat sink is a passive device that is used to dissipate heat generated by electronic devices. Its primary function is to transfer heat from the electronic components to the surrounding environment, thus preventing the device from overheating and malfunctioning. The heat sink is made of a material with high thermal conductivity, such as copper or aluminum, which facilitates the transfer of heat.

The function of a heat sink is critical in modern technology, where electronic devices generate significant amounts of heat during operation. The heat sink helps to maintain the temperature of the device within safe limits, preventing damage to the components and ensuring that the device operates reliably.

In addition to its functional role, the heat sink also plays a critical role in the design of electronic devices. It is often integrated into the device itself, and its size and shape are carefully chosen to maximize its cooling capabilities. The heat sink may be designed to allow for airflow or liquid cooling, depending on the specific requirements of the device.

Overall, the heat sink is an essential component in the design of electronic devices, and its proper functioning is critical to the reliability and longevity of these devices.

How Does a Heat Sink Work?

Principles of Heat Transfer

- Introduction to heat transfer

Heat transfer is the process by which heat is transferred from one object to another due to a temperature difference. It is a fundamental concept in thermodynamics and plays a crucial role in the functioning of various systems, including heat sinks.

- Conduction, convection, and radiation

There are three main mechanisms of heat transfer: conduction, convection, and radiation.

Conduction is the transfer of heat through direct contact between objects. When two objects with different temperatures are in contact, heat flows from the hotter object to the cooler object until both objects reach the same temperature. This process occurs due to the movement of heat-carrying particles within the objects.

Convection is the transfer of heat through the movement of fluids. In the case of heat sinks, convection occurs when hot air or fluid flows over the surface of the heat sink, carrying away heat from the object. This is the reason why heat sinks are often designed with fins or other surface irregularities to increase the surface area for convection.

Radiation is the transfer of heat through electromagnetic waves. All objects emit thermal radiation, and when an object is at a higher temperature than its surroundings, it emits more radiation than it absorbs. This is how a heat sink can transfer heat to the surrounding air or fluid, even if there is no direct contact between the two.

- How heat sinks utilize these mechanisms

Heat sinks are designed to utilize all three mechanisms of heat transfer in order to efficiently dissipate heat from an object. They typically have a large surface area to increase the rate of conduction and convection, and they may also be made of materials that are good conductors of heat to facilitate conduction. Additionally, heat sinks may be designed with fins or other surface irregularities to increase the surface area for convection. Finally, heat sinks may be coated with materials that are good emitters of thermal radiation to enhance radiation heat transfer. By utilizing all three mechanisms of heat transfer, heat sinks are able to effectively dissipate heat and prevent overheating in the objects they are designed to protect.

Materials Used in Heat Sinks

Types of materials used in heat sinks

In designing a heat sink, the materials used play a crucial role in determining its effectiveness. The primary goal is to maximize the surface area to facilitate heat transfer while maintaining structural integrity. Some common materials used in heat sinks include:

- Aluminum: This is the most widely used material for heat sinks due to its low cost, high thermal conductivity, and corrosion resistance. It is commonly used in computer CPUs and other electronic devices.

- Copper: Copper has a high thermal conductivity, making it an excellent material for heat sinks. It is commonly used in high-performance CPU coolers and other applications where high heat transfer is required.

- Silver: Silver has an even higher thermal conductivity than copper, making it an ideal material for heat sinks in high-performance computing applications. However, its high cost limits its use to specialized applications.

Factors to consider when choosing materials

When selecting materials for a heat sink, several factors must be considered:

- Thermal conductivity: The material’s ability to conduct heat is a critical factor in determining its effectiveness.

- Cost: The cost of the material is an essential consideration, especially when choosing between materials with similar thermal conductivity.

- Durability: The material must be able to withstand the conditions it will be subjected to during operation.

- Corrosion resistance: The material must be resistant to corrosion to ensure long-term performance.

Common materials used in heat sinks

Some common materials used in heat sinks include:

- Aluminum: As mentioned earlier, aluminum is the most widely used material for heat sinks due to its low cost, high thermal conductivity, and corrosion resistance.

- Copper: Copper is an excellent material for heat sinks due to its high thermal conductivity. It is commonly used in high-performance CPU coolers and other applications where high heat transfer is required.

- Carbon composites: Carbon composites are becoming increasingly popular in heat sink design due to their high thermal conductivity and low weight. They are commonly used in high-performance applications such as aerospace and automotive engines.

Design and Structure of Heat Sinks

Design considerations for heat sinks:

When designing a heat sink, several factors must be considered to ensure optimal performance. These factors include:

- Material selection: The material used for the heat sink will affect its thermal conductivity, weight, and cost. Common materials include aluminum, copper, and composite materials.

- Surface area: The larger the surface area of the heat sink, the better it can dissipate heat. The surface area can be increased by using fins or extrusions.

- Heat sink geometry: The shape of the heat sink can also affect its performance. A flat plate heat sink is simpler and more efficient than a finned heat sink for many applications.

- Airflow: The heat sink must be designed to allow for adequate airflow to dissipate the heat. The orientation of the heat sink and the placement of the fan can affect the airflow.

Structure and components of a heat sink:

The structure of a heat sink consists of a base, fins, and a mounting system. The base is in contact with the component that generates heat, and the fins increase the surface area for heat dissipation. The mounting system holds the heat sink in place and may include screws, clips, or thermal tape.

Factors affecting the performance of a heat sink:

Several factors can affect the performance of a heat sink, including:

- Ambient temperature: The heat sink’s performance will be affected by the ambient temperature of the surrounding environment.

- Airflow: Adequate airflow is necessary for the heat sink to dissipate heat effectively.

- Heat load: The heat sink’s performance will be affected by the amount of heat that it must dissipate.

- Thermal resistance: The thermal resistance of the heat sink will affect its performance. A lower thermal resistance means better heat dissipation.

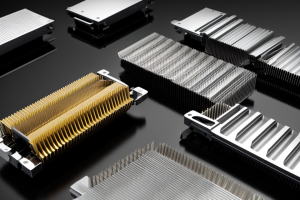

Heat Sink Fin Configuration

Introduction to fins

In the context of heat sinks, fins are small protrusions or extended surfaces that are designed to increase the surface area of the heat sink and facilitate heat dissipation. These fins come in various shapes and sizes, and their arrangement plays a crucial role in determining the efficiency of the heat sink.

Types of fin configurations

There are several types of fin configurations used in heat sinks, each with its own advantages and disadvantages. Some of the most common configurations include:

- Flat plates: In this configuration, the fins are flat and parallel to each other. This design is simple and easy to manufacture, but it may not be as efficient as other configurations.

- Flared fins: These fins are curved and flare out from the base of the heat sink. This design increases the surface area of the heat sink and can improve heat dissipation, but it may also create turbulence and increase resistance.

- Convection fins: These fins are designed to promote convection, which is the movement of heat-carrying fluids. This design can improve heat transfer, but it may also create noise and require more space.

- Liquid-cooled fins: In this configuration, the fins are cooled by a liquid that flows through them. This design can be very efficient, but it may also be more complex and expensive to manufacture.

Advantages and disadvantages of different fin configurations

The choice of fin configuration depends on the specific requirements of the application. Each configuration has its own advantages and disadvantages, and the optimal choice will depend on factors such as the size and shape of the heat sink, the type of heat source, and the desired level of efficiency.

For example, flat plates may be suitable for small heat sinks and simple applications, while flared fins may be more appropriate for larger heat sinks and higher heat loads. Convection fins may be useful for applications where noise is not a concern, and liquid-cooled fins may be ideal for high-performance applications where space is not a limitation.

In conclusion, the choice of fin configuration is critical to the performance of a heat sink. Understanding the advantages and disadvantages of each configuration can help engineers and designers make informed decisions and optimize the performance of their heat sinks.

Does Water Heat Sink?

Explanation of Water as a Heat Sink

Water, as a heat sink, is an effective means of dissipating heat generated by various processes, such as in the cooling systems of power plants, industrial facilities, and even in residential settings. The unique properties of water make it an excellent heat sink due to its high specific heat capacity, high thermal conductivity, and low viscosity.

- High Specific Heat Capacity: Water has a high specific heat capacity, which means it can absorb and release a large amount of heat energy without a significant change in temperature. This property makes water an effective heat sink as it can absorb heat from a source and disperse it over a larger area without a significant rise in temperature.

- High Thermal Conductivity: Water has a high thermal conductivity, which means it can transfer heat quickly and efficiently from one point to another. This property is crucial in heat sink applications as it ensures that heat is transferred quickly and uniformly, preventing localized overheating.

- Low Viscosity: Water has a low viscosity, which means it flows easily and can be pumped through pipes and channels with minimal resistance. This property is essential in heat sink applications where the water needs to be circulated through a system to dissipate heat effectively.

Water is often compared to other materials as a heat sink, and it is found to be more effective than most other materials. This is due to its unique combination of properties, which make it an efficient and reliable heat sink. In addition, water is also non-toxic, non-corrosive, and readily available, making it an ideal choice for a wide range of heat sink applications.

Water Heat Sink Examples

Real-life Examples of Water Heat Sinks

One real-life example of a water heat sink is a car’s radiator. The radiator is designed to dissipate the heat generated by the car’s engine, and it uses water as the heat sink. The hot water is pumped through the radiator, where it is cooled by the air passing through the grille and the fan. The cooled water is then recirculated through the engine to absorb more heat.

Another example of a water heat sink is a heat exchanger, which is commonly used in HVAC systems. A heat exchanger is a device that transfers heat between two fluids, and it is often used to cool hot water or gases. In a heat exchanger, the hot water or gas passes through a series of tubes, and the heat is transferred to a second fluid, such as air or water, that flows over the outside of the tubes.

Case Studies of Water Heat Sink Applications

There have been several case studies of water heat sink applications in industrial settings. For example, a paper mill in Sweden installed a water heat sink system to recover heat from its process water. The system consisted of a heat exchanger and a storage tank, and it was able to reduce the mill’s energy consumption by 20%.

Another case study involved a brewery in the United Kingdom that installed a water heat sink system to recover heat from its wastewater. The system consisted of a heat exchanger and a cooling tower, and it was able to reduce the brewery’s energy consumption by 30%.

Analysis of the Effectiveness of Water Heat Sinks

Several studies have been conducted to analyze the effectiveness of water heat sinks. One study found that water heat sinks can be up to 80% more efficient than air heat sinks in certain applications. Another study found that water heat sinks can be more effective than air heat sinks in removing heat from electronic components, as water has a higher thermal conductivity than air.

Overall, water heat sinks have proven to be an effective method for removing heat from a variety of applications, and they are widely used in industrial and commercial settings.

Factors Affecting Water Heat Sink Performance

Factors that affect the performance of a water heat sink

- Water Temperature: The temperature of the water affects the performance of a water heat sink. As the temperature of the water increases, the heat sink’s ability to transfer heat decreases.

- Flow Rate: The flow rate of the water also affects the performance of a water heat sink. A higher flow rate will result in a higher heat transfer rate.

- Surface Area: The surface area of the heat sink also plays a crucial role in its performance. A larger surface area will result in a higher heat transfer rate.

- Material: The material used to make the heat sink also affects its performance. Materials with high thermal conductivity, such as copper, will result in a higher heat transfer rate.

Environmental factors

- Ambient Temperature: The ambient temperature of the surroundings can affect the performance of a water heat sink. A higher ambient temperature will result in a lower heat transfer rate.

- Humidity: The humidity of the surroundings can also affect the performance of a water heat sink. High humidity can result in a lower heat transfer rate.

Design considerations

- Heat Source Location: The location of the heat source relative to the heat sink can affect its performance. The heat sink should be placed as close as possible to the heat source for maximum heat transfer.

- Insulation: Proper insulation of the heat sink can improve its performance by reducing heat loss to the surroundings.

- Fin Configuration: The configuration of the fins on the heat sink can also affect its performance. Fins increase the surface area of the heat sink and improve its ability to transfer heat.

Other Heat Sink Materials

Alternatives to Water Heat Sinks

Overview of Other Heat Sink Materials

When it comes to heat sinks, water is not the only material that can be used to dissipate heat. There are several other materials that can be used as heat sinks, each with its own advantages and disadvantages. Some of the most common alternatives to water heat sinks include:

- Metal heat sinks: Metal heat sinks are widely used in electronic devices because they are effective at dissipating heat and can be easily shaped and molded to fit the specific needs of a device. Metals such as aluminum and copper are commonly used because they have high thermal conductivity, meaning they can transfer heat quickly and efficiently.

- Silicon-based heat sinks: Silicon-based heat sinks are becoming increasingly popular because they are lightweight, compact, and have a high thermal conductivity. They are often used in small electronic devices such as smartphones and laptops.

- Phase change materials (PCMs): PCMs are materials that change phase (such as melting or freezing) at a specific temperature. They are often used as heat sinks in applications where temperature control is important, such as in thermostats and refrigeration systems.

- Evaporative cooling: Evaporative cooling is a process in which a liquid is vaporized to absorb heat. This process is often used in cooling towers and air conditioning systems.

Advantages and Disadvantages of Different Materials

Each type of heat sink material has its own advantages and disadvantages. For example:

- Metal heat sinks: Metals are effective at dissipating heat, but they can be heavy and bulky. They are also prone to corrosion, which can reduce their effectiveness over time.

- Silicon-based heat sinks: Silicon-based heat sinks are lightweight and compact, but they may not be as effective at dissipating heat as metal heat sinks. They are also more expensive than metals.

- Phase change materials (PCMs): PCMs are effective at maintaining a constant temperature, but they can be expensive and may not be suitable for all applications.

- Evaporative cooling: Evaporative cooling is effective in humid environments, but it can be less effective in dry environments. It also requires a constant supply of water, which can be a concern in areas with limited water resources.

Comparison with Water Heat Sinks

When compared to water heat sinks, other materials have their own advantages and disadvantages. For example:

Overall, the choice of heat sink material depends on the specific needs of the application. Factors such as the size and shape of the device, the environment in which it will be used, and the required temperature range must all be considered when choosing a heat sink material.

Emerging Technologies in Heat Sink Materials

In recent years, there has been significant progress in the development of emerging heat sink technologies. These advancements aim to improve the efficiency and performance of heat sinks in various applications. This section will explore some of the new materials and designs being introduced and their potential future prospects.

Introduction to emerging heat sink technologies

Heat sink technology has come a long way since its inception. With the increasing demand for efficient thermal management solutions, researchers and engineers are continuously exploring new materials and designs to improve heat sink performance. Emerging heat sink technologies focus on enhancing thermal conductivity, improving heat transfer, and reducing thermal resistance.

Examples of new materials and designs

Some of the emerging heat sink materials and designs include:

- Graphene-based heat sinks: Graphene’s high thermal conductivity and mechanical flexibility make it an ideal material for heat sink applications. Graphene-based heat sinks offer improved thermal performance and reduced thermal resistance compared to traditional materials.

- Phase Change Materials (PCMs): PCMs are materials that undergo a change in phase (e.g., melting or freezing) during a temperature change. By incorporating PCMs into heat sinks, the thermal storage capacity can be increased, resulting in improved thermal performance and efficiency.

- Nanofluids: Nanofluids are colloidal suspensions of nanoparticles in a base fluid. The addition of nanoparticles enhances the thermal conductivity of the base fluid, resulting in improved heat transfer capabilities.

- 3D-printed heat sinks: 3D printing technology allows for the creation of complex heat sink geometries that can optimize heat transfer and reduce thermal resistance. This technology enables customized heat sink designs for specific applications.

Future prospects for heat sink technology

As the demand for efficient thermal management solutions continues to grow, it is expected that emerging heat sink technologies will play a crucial role in shaping the future of heat sink design. These innovations have the potential to significantly improve the performance and efficiency of heat sinks in various industries, including electronics, automotive, and aerospace. Additionally, the integration of renewable energy sources and the increasing focus on sustainability may lead to the development of eco-friendly heat sink materials and designs.

Overall, the future of heat sink technology looks promising, with ongoing research and development aimed at improving thermal performance and efficiency. As these emerging technologies continue to advance, they will contribute to the development of more effective heat sink solutions for a wide range of applications.

FAQs

1. What is a heat sink?

A heat sink is a component used in electronics to dissipate excess heat generated by the device. It is typically made of a material with high thermal conductivity, such as copper or aluminum, and has a large surface area to facilitate heat transfer.

2. How does a heat sink work?

A heat sink works by transferring heat from the device to the surrounding environment. The heat sink absorbs the heat generated by the device and transfers it to the air or liquid in contact with it. This process continues until the heat sink reaches a temperature equal to the surrounding environment or the device reaches a safe operating temperature.

3. Can water be used as a heat sink?

Yes, water can be used as a heat sink, but it is not as effective as other materials such as metal. Water has a lower thermal conductivity than metals, which means it takes longer to transfer heat. Additionally, water can only be used as a heat sink if it is in contact with a surface that is at a lower temperature than the heat sink, otherwise it will not transfer heat.

4. How does water temperature affect its ability to heat sink?

The temperature of the water affects its ability to heat sink. Warmer water is less effective at transferring heat than cooler water. Additionally, if the water is at the same temperature as the heat sink, it will not transfer heat. Therefore, it is important to use cold water as a heat sink to maximize its effectiveness.

5. What are some applications where water can be used as a heat sink?

Water can be used as a heat sink in applications such as cooling systems for electronic devices, industrial cooling systems, and in cooling towers. It is also used in heat exchangers, where warm water is used to cool down a hot fluid, such as oil or gas.

6. Are there any disadvantages of using water as a heat sink?

One disadvantage of using water as a heat sink is that it can be corrosive, especially if it is used with metals that are not compatible with water. Additionally, water can be a source of noise and vibration, which can be a problem in some applications. Finally, water can be a source of bacteria and other microorganisms, which can be a concern in some industrial applications.