When it comes to cooling your electronics, the question of whether a heat sink or liquid cooling is better is a hot topic. Heat sinks, which are passive cooling systems that rely on natural convection, have been around for a long time and are widely used in many electronic devices. However, liquid cooling, which uses a liquid coolant to remove heat from the components, has become increasingly popular in recent years due to its ability to provide more efficient cooling. In this article, we will explore the pros and cons of both heat sinks and liquid cooling and help you determine which one is the better choice for your electronic devices. So, let’s dive in and find out which one will keep your electronics cool and running smoothly.

A heat sink is a passive component that can be used to dissipate heat from electronic components. It is designed to transfer heat from the components to the surrounding environment. A heat sink can be a better choice for cooling electronic components if the components generate a significant amount of heat and the environment is cooler than the components. The heat sink should be designed to match the specific requirements of the components and the environment. However, in some cases, active cooling methods such as fans or refrigeration may be more effective in removing heat from the components.

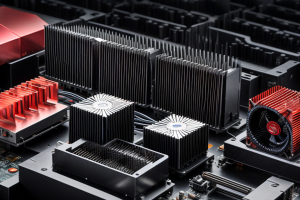

What is a Heat Sink?

Definition and Purpose

A heat sink is a passive cooling solution used to dissipate heat generated by electronic components. It is designed to increase the surface area available for heat transfer to the surrounding environment, thus reducing the temperature of the component.

The primary purpose of a heat sink is to extend the lifespan of electronic devices by preventing overheating, which can cause damage to the components and lead to malfunction or failure. By increasing the surface area available for heat transfer, a heat sink can effectively lower the temperature of the electronic component, thereby improving its overall performance and longevity.

In addition to its primary purpose, a heat sink also plays a crucial role in improving the reliability and efficiency of electronic systems. By reducing the temperature of the components, a heat sink can improve their performance and reduce the risk of failure due to overheating. This is particularly important in applications where electronic systems are subjected to high levels of stress or operate in extreme environments, such as in automotive, aerospace, and industrial applications.

Overall, the definition and purpose of a heat sink is to provide an effective and reliable solution for cooling electronic components, thereby improving their performance and longevity. By increasing the surface area available for heat transfer, a heat sink can effectively lower the temperature of the electronic component, thereby reducing the risk of failure due to overheating and improving the reliability and efficiency of electronic systems.

Types of Heat Sinks

When it comes to choosing a heat sink for cooling your electronics, it’s important to understand the different types available. Some of the most common types of heat sinks include:

- Air-cooled heat sinks: These heat sinks use the surrounding air to dissipate heat. They are often used in smaller electronics, such as personal computers and laptops.

- Water-cooled heat sinks: These heat sinks use water to transfer heat away from the electronics. They are often used in larger systems, such as servers and data centers.

- Liquid-to-air heat sinks: These heat sinks use a liquid coolant to transfer heat away from the electronics, and then the liquid is cooled by the surrounding air. They are often used in high-performance computers and gaming systems.

- Phase-change heat sinks: These heat sinks use a phase change material, such as wax or metal, to absorb and transfer heat away from the electronics. They are often used in applications where there is a need for a high degree of thermal stability, such as in scientific research or laboratory settings.

Understanding the different types of heat sinks available can help you choose the best one for your specific needs. It’s important to consider factors such as the size and complexity of your system, the amount of heat that needs to be dissipated, and the type of coolant available when selecting a heat sink.

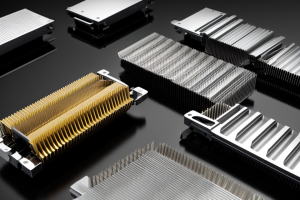

How Does it Work?

A heat sink is a passive device that is used to dissipate heat generated by electronic components. It is typically made of metal and has a large surface area that allows it to transfer heat away from the electronic components to the surrounding environment.

The basic principle behind how a heat sink works is based on the concept of thermal conduction. When the heat sink is in contact with the electronic components, the heat is transferred from the components to the heat sink through a process called conduction. The heat sink then transfers this heat to the surrounding environment through convection and radiation.

Convection is the process by which heat is transferred through the movement of fluids. In the case of a heat sink, the fluid is usually air. As the heat sink increases the temperature of the surrounding air, the air molecules gain kinetic energy and move away from the heat sink, carrying the heat with them.

Radiation is the process by which heat is transferred through electromagnetic waves. A heat sink will also radiate heat to its surroundings, further dissipating the heat generated by the electronic components.

The design of a heat sink is critical to its effectiveness. The heat sink must have a large surface area in contact with the electronic components to facilitate efficient heat transfer. Additionally, the heat sink must be made of a material with high thermal conductivity, such as copper or aluminum, to facilitate the transfer of heat.

Overall, a heat sink is an effective solution for cooling electronic components, and is often used in applications where other cooling methods, such as fans or liquid cooling, are not practical or desirable.

Liquid Cooling: The Alternative

Liquid cooling is a method of removing heat from electronic components by using a liquid coolant that circulates through a closed-loop system. The primary purpose of liquid cooling is to dissipate heat generated by the electronic components and maintain a safe operating temperature. Unlike air cooling, liquid cooling uses a liquid coolant that absorbs heat and transfers it to a heat exchanger, where it can be dissipated to the ambient air or atmosphere.

One of the advantages of liquid cooling is that it can provide more efficient heat transfer than air cooling, particularly in high-performance computing applications. Liquid cooling can also offer a lower noise profile compared to air cooling, as the liquid coolant does not generate noise during operation.

In addition to its benefits, liquid cooling also has some challenges associated with it. The system requires regular maintenance, including monitoring the liquid coolant level, cleaning the system, and replacing the coolant periodically. Additionally, the system may require specialized hardware and expertise to set up and maintain.

Types of Liquid Cooling Systems

Liquid cooling systems use a liquid, typically water or a mixture of water and glycol, to remove heat from the electronic components. The liquid is circulated through a system of pipes and heat exchangers, transferring the heat to a radiator or other heat dissipation device. There are two main types of liquid cooling systems:

- Closed-loop systems: In a closed-loop system, the liquid coolant is contained within a closed loop, typically using a pump to circulate the liquid. The liquid is usually contained within a sealed, pressurized system, which reduces the risk of leaks.

- Open-loop systems: In an open-loop system, the liquid coolant is circulated through a heat exchanger, which is usually a radiator or a set of copper pipes with a fan blowing air over them. The advantage of an open-loop system is that it is less expensive and more flexible than a closed-loop system, but it is also more prone to leaks and requires more maintenance.

Both types of liquid cooling systems have their advantages and disadvantages, and the choice of which one to use will depend on the specific needs of the electronic system being cooled. Closed-loop systems are more efficient and reliable, but they are also more expensive and require more maintenance. Open-loop systems are less expensive and more flexible, but they are also more prone to leaks and require more maintenance.

Liquid cooling is a method of removing heat from electronic components by using a liquid coolant that flows through a closed-loop system. The coolant absorbs heat from the components and carries it away to a radiator, where it is released into the ambient air. This process continues continuously while the system is in operation.

One advantage of liquid cooling is that it can be more efficient than air cooling, especially in situations where there is a high heat load or limited space for airflow. Liquid cooling can also be quieter than air cooling, as the liquid coolant does not create turbulence or noise as it flows through the system.

Another advantage of liquid cooling is that it can be used to cool high-performance components, such as CPUs and GPUs, that generate a lot of heat. This is because liquid cooling can provide a more consistent temperature across the component, which can help to prevent thermal throttling and improve performance.

However, liquid cooling can also be more complex and expensive to implement than air cooling. It requires a dedicated pump and radiator, as well as fittings and tubing to connect the components. In addition, the liquid coolant itself can be more expensive than air cooling, and it may require more maintenance to ensure that it is free from leaks and other issues.

Overall, liquid cooling can be a good choice for cooling high-performance electronics, but it may not be necessary for all applications. It is important to carefully consider the pros and cons of liquid cooling before deciding whether it is the best choice for your needs.

Advantages and Disadvantages

Advantages

- Efficient cooling: Liquid cooling systems are designed to transfer heat away from the components more efficiently than air cooling systems. They use liquid to absorb heat and transfer it to a radiator, where it can be dissipated into the air. This allows for better thermal conductivity and faster heat dissipation, making it ideal for high-performance systems.

- Quiet operation: Liquid cooling systems are generally quieter than air cooling systems, as there are no fans or moving parts that can generate noise. This makes it an ideal choice for applications where noise reduction is critical, such as data centers or server rooms.

- Flexibility: Liquid cooling systems are highly flexible and can be customized to meet specific cooling requirements. They can be designed to cool specific components or areas of a system, and can be easily scaled up or down to meet changing demands.

Disadvantages

- Complexity: Liquid cooling systems are more complex than air cooling systems, and require more maintenance and setup. They require specialized equipment, such as pumps, reservoirs, and radiators, which can be expensive and difficult to install.

- Leakage: Liquid cooling systems are susceptible to leakage, which can cause damage to components and systems. If not installed correctly, leaks can cause damage to electrical components, and may even result in short circuits or other issues.

- Maintenance: Liquid cooling systems require regular maintenance, such as checking fluid levels, replacing worn parts, and cleaning the system. This can be time-consuming and requires specialized knowledge, which may make it less practical for some users.

In summary, liquid cooling systems offer several advantages over air cooling systems, including efficient cooling, quiet operation, and flexibility. However, they also have some disadvantages, such as complexity, leakage, and maintenance requirements. Understanding these advantages and disadvantages can help users make an informed decision when choosing a cooling solution for their electronics.

Comparing Heat Sinks and Liquid Cooling

Factors to Consider

When deciding between a heat sink and liquid cooling for cooling your electronics, there are several factors to consider.

- Thermal Performance: Both heat sinks and liquid cooling can provide effective thermal performance, but they do so in different ways. Heat sinks rely on natural convection and radiation to dissipate heat, while liquid cooling uses a liquid coolant to transfer heat away from the electronics. In general, liquid cooling can provide better thermal performance, but it can also be more expensive and more complex to set up.

- Noise Levels: Heat sinks tend to be quieter than liquid cooling systems, as they don’t have the noise generated by the movement of liquid coolant. This can be an important factor to consider if the electronics are located in a quiet environment, such as a data center or home theater.

- Maintenance: Heat sinks require little to no maintenance, as they have no moving parts. Liquid cooling systems, on the other hand, require regular maintenance to ensure that the coolant is clean and the system is functioning properly. This can include flushing the system, replacing coolant, and checking for leaks.

- Compatibility: Heat sinks are generally more compatible with a wider range of electronics than liquid cooling systems. This is because heat sinks can be customized to fit the specific dimensions and shape of the electronics, while liquid cooling systems often require specific components to be compatible with the coolant.

- Cost: Heat sinks are generally less expensive than liquid cooling systems, both in terms of the initial purchase price and ongoing maintenance costs. However, the cost of a heat sink can also depend on the size and complexity of the electronics being cooled.

Ultimately, the best choice between a heat sink and liquid cooling will depend on the specific needs and requirements of your electronics. It’s important to carefully consider all of the factors outlined above before making a decision.

When to Use a Heat Sink

While liquid cooling has its advantages, there are situations where a heat sink is the better choice for cooling your electronics. Here are some scenarios where a heat sink may be preferred:

- Simple and cost-effective:

Heat sinks are relatively simple and inexpensive compared to liquid cooling systems. They do not require complex plumbing or maintenance, making them a suitable option for those who do not want to invest in expensive cooling solutions. - Low volume cooling needs:

If your electronics do not generate a significant amount of heat, a heat sink may be sufficient for cooling purposes. For example, low-powered CPUs and small-scale embedded systems can be effectively cooled by a heat sink. - Fixed or limited space:

Heat sinks are often more compact than liquid cooling systems, making them a better choice when space is limited or when there are size constraints on the cooling solution. This can be particularly beneficial in small form factor PCs, embedded systems, or devices with tight spatial requirements. - Higher reliability:

In some cases, a heat sink may offer a higher level of reliability compared to liquid cooling. This is because heat sinks do not rely on pumps or other mechanical components that can fail over time, reducing the risk of downtime or system failures. - Operating environment:

Heat sinks are well-suited for environments where there is minimal exposure to dust, moisture, or other contaminants. They are often preferred in cleanroom or laboratory settings where the risk of contamination is low.

It is important to note that the suitability of a heat sink for a specific application depends on several factors, including the heat output of the electronics, the available space, and the desired level of reliability and performance. As such, it is crucial to carefully evaluate the cooling requirements of your electronics before making a decision on whether to use a heat sink or liquid cooling.

When to Use Liquid Cooling

Liquid cooling is a highly effective method of cooling electronics, especially in situations where heat dissipation is critical. There are several scenarios in which liquid cooling is the better choice over heat sinks.

- High-performance computing: Liquid cooling is often used in high-performance computing applications, such as data centers and supercomputers, where heat dissipation is critical to maintaining optimal performance.

- High-powered electronic devices: Devices that generate a lot of heat, such as gaming computers and high-end graphics cards, can benefit from liquid cooling. This is because liquid cooling can dissipate heat more efficiently than air cooling, which can be beneficial in these situations.

- Space-constrained environments: In situations where there is limited space for cooling solutions, liquid cooling can be a better choice than heat sinks. This is because liquid cooling systems are often more compact than heat sink-based cooling systems.

- Customizable cooling solutions: Liquid cooling systems can be customized to meet the specific cooling needs of different electronics. This makes them a good choice for situations where a standard heat sink-based cooling solution may not be sufficient.

Overall, liquid cooling is a highly effective method of cooling electronics, and is particularly useful in situations where heat dissipation is critical.

Further Reading

For those looking to further explore the topic of heat sinks and liquid cooling for electronics, there are several resources available that provide in-depth information and expert insights. Here are a few recommendations:

- Thermal Management of Electronics by Ali S. Mian and Hisham A. Al-Mashaqbe: This book provides a comprehensive overview of thermal management techniques for electronics, including the use of heat sinks and liquid cooling systems. It covers the fundamentals of heat transfer, as well as advanced topics such as computational fluid dynamics and phase change materials.

- Heat Sink Handbook by Michael E. Flatt and Li-Ping Liu: This handbook is a practical guide to the design and application of heat sinks. It covers a wide range of topics, including the selection of materials, design considerations, and thermal simulation techniques. The book also includes case studies and examples to illustrate real-world applications.

- Liquid Cooling for Computers by Andreas L. Zimmer: This book is a detailed guide to the design and implementation of liquid cooling systems for computers. It covers the physics of heat transfer, as well as the design and selection of components such as pumps, radiators, and tubing. The book also includes case studies and practical tips for building and maintaining liquid cooling systems.

- TechPowerUp! (https://www.techpowerup.com/): TechPowerUp! is a website that provides in-depth reviews and articles on computer hardware, including cooling systems. The site features detailed reviews of heat sinks and liquid cooling systems, as well as tutorials and guides on how to build and maintain these systems.

- Tom’s Hardware (https://www.tomshardware.com/): Tom’s Hardware is a website that provides news, reviews, and tutorials on computer hardware. The site features articles on cooling systems, including heat sinks and liquid cooling systems, as well as expert advice on how to choose and install these systems.

By exploring these resources, readers can gain a deeper understanding of the pros and cons of heat sinks and liquid cooling systems for electronics, as well as the latest trends and developments in this field.

FAQs

1. What is a heat sink?

A heat sink is a passive cooling solution that transfers heat from an electronic component to the surrounding environment. It consists of a metal casing with fins or ridges that increase the surface area for heat dissipation. The heat sink is designed to conduct heat away from the component and disperse it into the air.

2. What is liquid cooling?

Liquid cooling is an active cooling solution that uses a liquid coolant to remove heat from electronic components. The liquid coolant is pumped through a radiator or heat exchanger, where it absorbs heat and carries it away from the components. Liquid cooling systems are typically more efficient than heat sinks and can handle higher heat loads.

3. When should I use a heat sink?

You should use a heat sink when your electronic components generate a moderate amount of heat and do not require advanced cooling solutions. Heat sinks are effective for cooling CPUs, GPUs, and other components that produce a reasonable amount of heat. However, if your components generate a large amount of heat, you may need to consider a liquid cooling solution.

4. When should I use liquid cooling?

You should use liquid cooling when your electronic components generate a large amount of heat and require advanced cooling solutions. Liquid cooling systems are designed to handle high heat loads and provide more efficient cooling than heat sinks. Additionally, liquid cooling systems can be customized to meet the specific cooling needs of your components.

5. Are heat sinks easier to install than liquid cooling?

Heat sinks are generally easier to install than liquid cooling systems. Heat sinks are passive cooling solutions that do not require any additional components or setup. Simply attach the heat sink to the component and place it in a well-ventilated area. Liquid cooling systems, on the other hand, require additional components such as pumps, radiators, and tubing, which can be more complex to install.

6. Are liquid cooling systems quieter than heat sinks?

Liquid cooling systems can be quieter than heat sinks, depending on the setup. Liquid cooling systems are designed to be quieter than traditional air cooling solutions, as the liquid coolant does not produce noise like fans in a heat sink. However, the pump and other components of a liquid cooling system can produce noise, so it is important to choose a system that is designed for quiet operation.

7. Can I use a heat sink and liquid cooling together?

It is possible to use a heat sink and liquid cooling together, but it is not recommended. Combining these two cooling solutions can result in inefficient cooling and may cause damage to the components. It is best to choose one cooling solution or the other based on the cooling needs of your components.